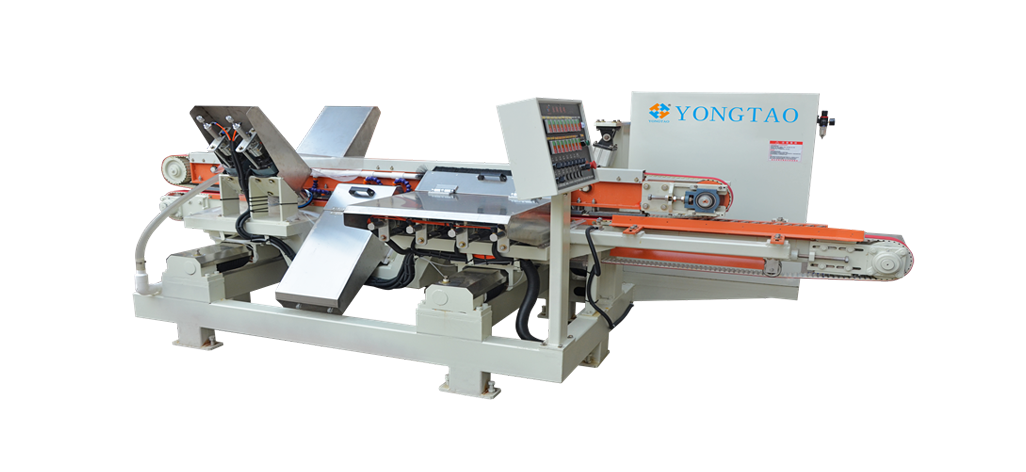

Yongtao Machinery has tailored a highly efficient granite edge profiling and polishing production line based on customer needs. This production line integrates three key machines, each equipped with 8 polishing heads, to fulfill the shaping and polishing requirements of granite edges. Ideal for large-scale production, it significantly enhances processing speed and polishing quality, ensuring precision and superior finish.

Precision Configuration to Enhance Processing Quality

This production line includes three specialized machines, each responsible for different processing tasks:

1、The first machine polishes the surface of the granite, ensuring smoothness and texture.

2、The second machine shapes and polishes the left edge of the granite, making it suitable for granite with complex edge details.

3、The third machine shapes and polishes the right edge, ensuring symmetrical and uniform edging.

Shaping uses electroplated wheels for high precision, while the polishing process utilizes resin polishing wheels and sponge polishing wheels for added gloss. The combination of these granite edge profiling machines and granite edge polishing machines enables simultaneous left and right edge processing, completing shaping and polishing in one pass.

Efficient Assembly Line Design for Enhanced Production

This granite edge profiling machine production line features an assembly line design that significantly improves production efficiency, reducing manual intervention and labor costs. Compared with traditional methods, this granite edge polishing machine line not only accelerates processing speed but also improves product smoothness and consistency, making it ideal for large-scale production requirements.

Application Advantages and Suitable Scenarios

This production line is ideal for granite edge processing that requires high precision and a polished finish. Its integrated molding and polishing functions leave granite products with smooth surfaces and well-defined edges. This production line is highly valuable for large granite processing plants, making it an ideal choice in the fields of granite edge profiling and molding.

Cost-effectiveness and Applicability

While this granite moulding and polishing production line comes with a higher price point, its efficient production speed and excellent polishing results justify the investment. It is especially suitable for companies requiring mass production of high-quality granite products. As one of the advanced pieces of equipment in the granite processing industry, this line significantly boosts production capacity and meets market demands.

14 Head Ceramic Tile edge polishing machine

10 30,2019

14 Head Ceramic Tile edge polishing machine

VIEW

14 Head Ceramic Tile edge polishing machine

10 30,2019

14 Head Ceramic Tile edge polishing machine

VIEW Two Blade Porcelain Tile Cutting Machine

10 30,2019

Two Blade Porcelain Tile Cutting Machine

VIEW

Two Blade Porcelain Tile Cutting Machine

10 30,2019

Two Blade Porcelain Tile Cutting Machine

VIEW YJ-4020-5L AC 5 axis water jet cutting machine

04 21,2020

Yongtao 4020 AC 5 axis water jet cutting machine,can cut tile,stone,marble,sintered stone at an Angle of 45 degrees.

Yongtao water jet cutting machine is a first-class technology company in China

VIEW

YJ-4020-5L AC 5 axis water jet cutting machine

04 21,2020

Yongtao 4020 AC 5 axis water jet cutting machine,can cut tile,stone,marble,sintered stone at an Angle of 45 degrees.

Yongtao water jet cutting machine is a first-class technology company in China

VIEW YSXP-150 6 Head Automatic Marble Molding Machine

04 15,2019

YSXP-150 6 Head Automatic Marble Molding Machine, this machine is the new generation product of YONGTAO Machinery. It has 2 heads to profile, and 4 heads to polish. The polishing wheel adopts an automatic control system. The machine adopts

VIEW

YSXP-150 6 Head Automatic Marble Molding Machine

04 15,2019

YSXP-150 6 Head Automatic Marble Molding Machine, this machine is the new generation product of YONGTAO Machinery. It has 2 heads to profile, and 4 heads to polish. The polishing wheel adopts an automatic control system. The machine adopts

VIEW YSMD 5+3+3 Multifunction Marble Edge Profile Chamfer Polishing Machine

04 15,2019

YSMD 5+3+3 Multifunction Marble Edge Profile Chamfer Polishing Machine,This machine is the new generation product of Yongtao Machinery. It can process single thick slab and double thick slab for all kinds of edge shapes, such as 180 degree round edge, fla

VIEW

YSMD 5+3+3 Multifunction Marble Edge Profile Chamfer Polishing Machine

04 15,2019

YSMD 5+3+3 Multifunction Marble Edge Profile Chamfer Polishing Machine,This machine is the new generation product of Yongtao Machinery. It can process single thick slab and double thick slab for all kinds of edge shapes, such as 180 degree round edge, fla

VIEW YCYP-2500 Quartz Countertop Edge Polishing Machine

05 14,2019

YCYP-2500 Quartz Countertop Edge Polishing Machine,The machine is mainly used to process the quartz countertop edges. It can do R3 round edge, calibrating, grooving, flat polishing. The machine have special pressure structure, each press roller drive bu i

VIEW

YCYP-2500 Quartz Countertop Edge Polishing Machine

05 14,2019

YCYP-2500 Quartz Countertop Edge Polishing Machine,The machine is mainly used to process the quartz countertop edges. It can do R3 round edge, calibrating, grooving, flat polishing. The machine have special pressure structure, each press roller drive bu i

VIEW YSMD 11 Head Automatic Granite Flat Bevel Edge Polishing Machine

04 15,2019

YSMD 11 Head Automatic Granite Flat Bevel Edge Polishing Machine,This machine is one of the latest models of YONGTAO Machinery.The machine is mainly used to process all kinds of single or double thick slab for flat edge, bevel edge, chamfer. It rely on th

VIEW

YSMD 11 Head Automatic Granite Flat Bevel Edge Polishing Machine

04 15,2019

YSMD 11 Head Automatic Granite Flat Bevel Edge Polishing Machine,This machine is one of the latest models of YONGTAO Machinery.The machine is mainly used to process all kinds of single or double thick slab for flat edge, bevel edge, chamfer. It rely on th

VIEW YSMDP-800 1+6-1+2 Stone Flat Bevel Edge Polishing Machine

10 24,2019

YSMDP-800 1+6-1+2 Stone Flat Bevel Edge Polishing Machine,this machine is applied to process the flat edge and bevel edge for the marble, granite stone slabs. Put the slab on the conveyor belt, the conveyor will drive the material into working area. There

VIEW

YSMDP-800 1+6-1+2 Stone Flat Bevel Edge Polishing Machine

10 24,2019

YSMDP-800 1+6-1+2 Stone Flat Bevel Edge Polishing Machine,this machine is applied to process the flat edge and bevel edge for the marble, granite stone slabs. Put the slab on the conveyor belt, the conveyor will drive the material into working area. There

VIEW YSMDP-250 4+2+2 Quartz Double Flat Bevel Edge Polishing Machine

10 08,2019

YSMDP-250 4+2+2 Quartz Double Flat Bevel Edge Polishing Machine,put the material on the conveyor belt, the bottom belt will transport the material into the working area, and the top belt will press the material. At the front of machine, there are 4 st

VIEW

YSMDP-250 4+2+2 Quartz Double Flat Bevel Edge Polishing Machine

10 08,2019

YSMDP-250 4+2+2 Quartz Double Flat Bevel Edge Polishing Machine,put the material on the conveyor belt, the bottom belt will transport the material into the working area, and the top belt will press the material. At the front of machine, there are 4 st

VIEW

[email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China