Water jet machinery is a high-precision mechanical device that uses high-pressure water flow and the impact of abrasive particles to cut various materials, such as metal, stone, ceramics, plastics, etc. It has the advantages of fast cutting speed, good cutting effect, simple operation and convenient maintenance. At the same time, there is no thermal deformation and chemical reaction during its cutting process, and no cutting heat-affected zone will be generated, so it can achieve very high cutting accuracy and surface quality. In addition, water jet machinery is also an environmentally friendly device, as it does not generate any harmful substances and pollutants during its cutting process, and does not cause any negative impact on the environment.

Water jet machinery can cut various shapes, such as straight line, curve, circle, square, special shape, etc., and has a very wide range of applications. In industrial production, water jet cutting machines can be used to manufacture various parts, mechanical accessories, handicrafts, etc. In the field of construction, waterjet cutting machines can be used for processing and decoration of stone, glass, ceramics and other materials.

The working principle of the water jet machine is to mix the high-pressure water flow compressed by the water pump and the abrasive, and spray it on the cutting head. The cutting head rotates at high speed to focus the water flow and the abrasive into a high-speed jet, generating a strong impact to achieve purpose of cutting. In order to ensure the cutting effect, water jet machines usually use a high-precision control system to control and adjust the trajectory of the cutting head and cutting parameters to achieve high-precision cutting.

In addition to high precision and efficiency, water jet machinery has many other advantages. First, waterjet cutting does not produce heat-affected zones and deformation, so the original properties and surface quality of the cut material can be maintained. Secondly, waterjet cutting does not need to use any harmful substances and chemicals, so it can protect the environment and human health. In addition, waterjet cutting can achieve unlimited cutting length, and can easily cut large materials and structural parts, improving production efficiency and processing capacity.

Water jet cutting tiles:

Of course, waterjet machinery has some limitations and considerations. Since waterjet cutting requires the use of high-pressure water flow and abrasives, it is necessary to pay attention to safety issues during operation to avoid accidents. In addition, the cutting efficiency of waterjet cutting is affected by factors such as the hardness and thickness of the material, and it may take longer to cut for particularly hard or thick materials. In addition, when using a waterjet cutting machine, proper maintenance and maintenance are required to ensure the normal operation and life of the equipment.

Waterjet machines are widely used for cutting and processing a wide variety of materials, including metal, stone, ceramics, composites, plastics, rubber, wood, and more. Among them, for some difficult materials, such as titanium alloy, high-speed steel, glass, ceramics, etc., traditional cutting methods are often difficult to achieve high-precision and high-efficiency cutting, but water jet cutting machines can easily handle it. In the field of industrial manufacturing, water jet machinery has become standard equipment in many industries, such as aerospace, automobile manufacturing, shipbuilding, construction engineering, electronic appliances, furniture manufacturing and so on. The application of waterjet cutting machine can not only improve production efficiency and product quality, but also save costs and resources, and has extensive market and social value.

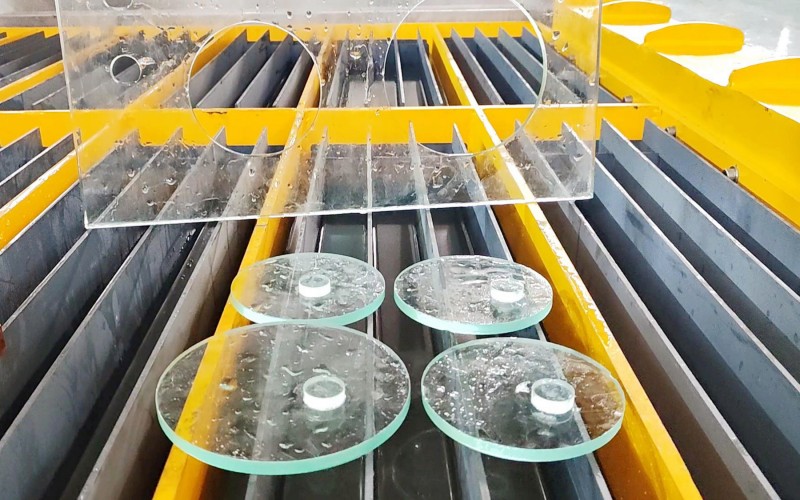

water jet cutting glass:

In short, the application fields of Yongtao water jet machinery are very wide, and new application scenarios and innovative developments are constantly emerging, and its role in modern production and social development will become more and more important.

[email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China