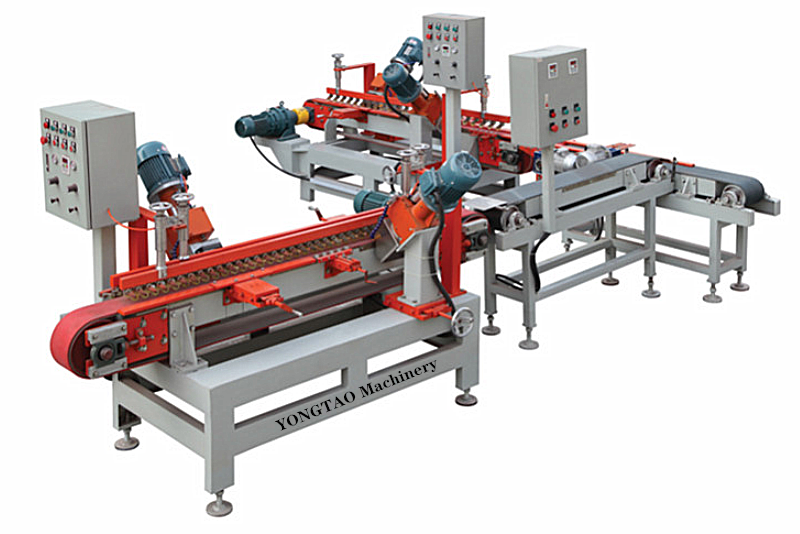

Yongtao mosaic cutting machine is a multi-purpose cutting equipment, suitable for cutting and grooving tiles and stones, cutting them into strips, squares, rhombuses and other shapes. This model has excellent processing capacity, and the processing width ranges from 22mm to 800mm. At the same time, it is equipped with a self-made pressing plate, which can realize the cutting of 10×10mm mosaics. The mosaic cutting machine has the advantages of reasonable design, high-precision machining capability, high cutting efficiency and large output.

Multi-Blade Mosaic Cutting Machine:

Mosaic cutting machine has the following features and functions:

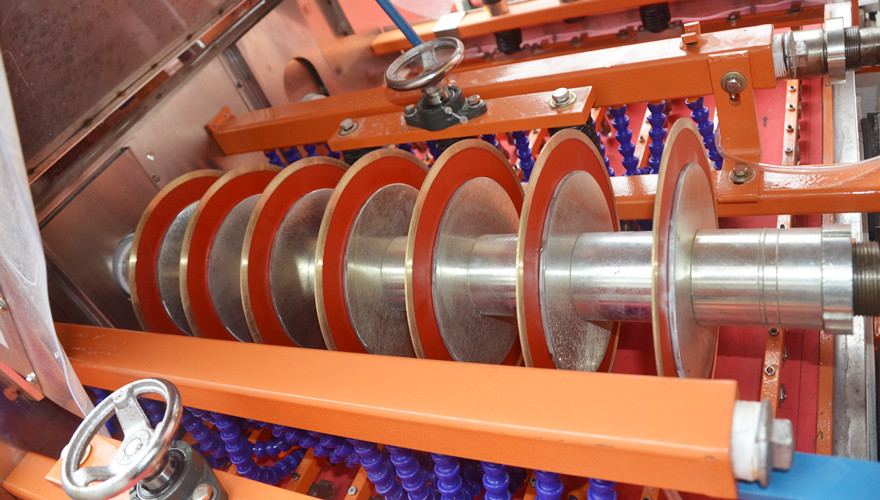

1. The headstock bearing housing adopts a water-cooling device to ensure that it will not generate heat or overheat during continuous long-term use, thereby prolonging the service life of the bearing.

2. The "V" belt guide system is adopted to ensure that the belt can be conveyed accurately.

Mosaic Chamfering Machine:

It is equipped with dovetail slot lift and double support gantry structure, which makes the cutting process more stable and reduces vibration. In order to operate the mosaic cutting machine correctly, please follow the steps below:

1. Connect the power supply according to the rated voltage of the machine or the local indicated voltage, and check whether the electrical components in the electric cabinet are in standby state.

2. When using for the first time, let the cutter head spindle idle for 30 minutes, let the conveyor belt run for 10 minutes, and observe whether it runs smoothly. If everything is fine, it's ready for production.

3. Turn on the power to the conveyor belt and cutter head, and check that the rotation of the conveyor belt and spindle is correct.

4. After installing the blade, tighten the spindle nut and adjust the position of the cooling water nozzle. The best direction is to make the water column fall on the position where the blade cuts the brick.

Mosaic Cutting Machine:

5. Start the power supply of the cutter head, and check whether the rotation of the spindle is consistent with the conveyor belt. Always make sure the blade is away from the conveyor belt before activating the power so as not to cut the conveyor belt.

6. Before commissioning the machine, place a brick on the brick stop of the conveyor belt, let the conveyor belt run, and adjust the pressure roller until the brick is firmly pressed. Take care to keep the side of the brick near the positioning board upright.

7. Use the control switch and the lifting button on the electric cabinet to adjust the depth of the bricks to be cut.

Yongtao mosaic cutting machine is specially designed for making high-grade mosaics. It can divide polished tiles into mosaics of various specifications, the minimum size can reach 10mm×10mm, and can realize various shapes, such as rhombus, hexagon, etc. This model has stable mechanical performance, especially when dividing small mosaics, it can stably press bricks to ensure that the cut small bricks will not fly out, thereby improving efficiency and ensuring quality.

Multi-blade cutting:

This mosaic cutting machine can also be used with mosaic templates to cut 15*15mm mosaic tiles.

Yongtao mosaic cutting machine adopts single-spindle cutting design, and each machine head can be equipped with multiple saw blades. It is suitable for dividing large-scale wall and floor tiles into required strip bricks, square bricks, rhombus bricks, square bricks, etc., and can realize cutting methods such as one split two, one split three, one split four. At the same time, this model also has the ability to divide bricks of different widths at one time, thereby greatly improving production efficiency without damage.

The mosaic cutting machine can hold up to a dozen saw blades and can cut bricks of different widths at one time. Its cutting error is only in the range of ±0.1mm, and it can accurately cut large-size wall and floor tiles into required sizes such as strip bricks, square bricks, and diamond-shaped bricks.

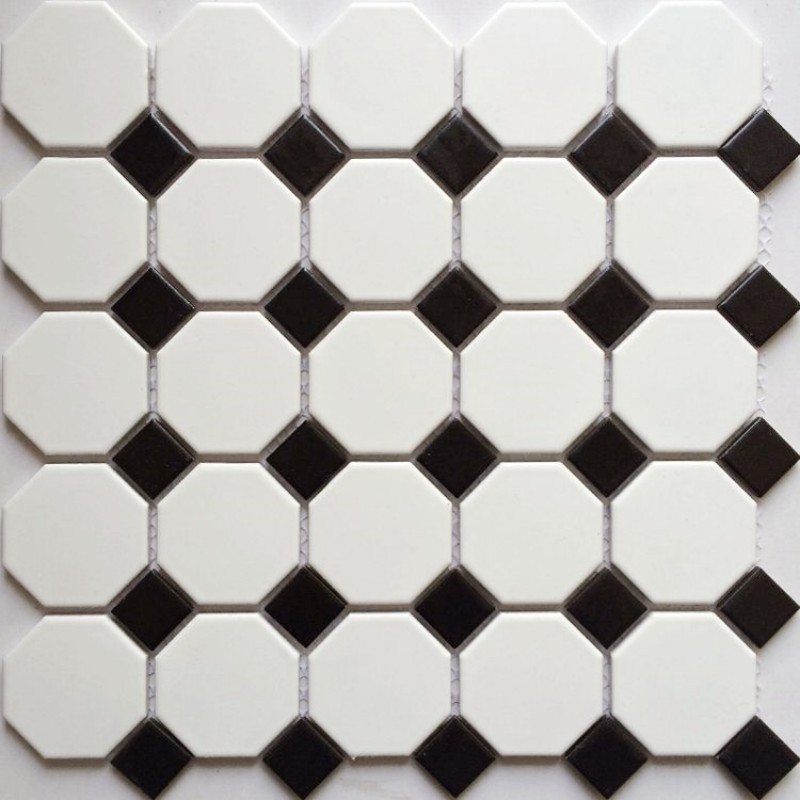

ceramic mosaic:

This model is suitable for processing tile mosaics, stone mosaics and small quartz stone cubes and other materials. Whether it is mass production or customized processing, Yongtao mosaic cutting machine can meet the needs of high quality and high efficiency, and provide stable and reliable processing solutions for the mosaic manufacturing industry.

Yongtao mosaic cutting machine has stable performance and excellent processing ability, which can be applied to the processing of various tile mosaics, stone mosaics and small quartz stone cubes. Whether it is small-scale custom production or large-scale mass production, this model can meet your needs, providing efficient, precise and high-quality cutting solutions.

Stone Mosaic:

[email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China