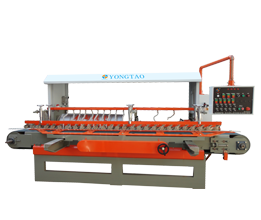

The Yongtao Stone Chamfering Machine features an upper and lower belt press structure, making it an ideal stone processing equipment for assembly line production. It is widely used for 45-degree chamfering of various materials such as stone, marble, quartz stone, and sintered stone. Its innovative belt press structure and assembly line production mode ensure precise processing while significantly improving production efficiency. Currently, the Yongtao Stone Chamfering Machine is available in two configurations: 4-head and 7-head models, utilizing a "cut first, grind later" process to meet various customer needs.

The Yongtao Marble Chamfering Machine can precisely perform 45-degree chamfering on L-shaped and U-shaped kitchen countertops, including front chamfering, middle chamfering, back chamfering, and 45-degree chamfering. Whether processing quartz kitchen countertops, sintered stone islands, or stone stair steps, the Yongtao Stone Chamfering Machine can handle all tasks with ease. The 45-degree adhesive bonding effect is impeccable, meeting most customers’ processing requirements. With a production speed of 1-2 meters per minute, it is particularly suitable for mass production in stone processing factories.

The Yongtao Quartz Chamfering Machine is especially suitable for the fine processing of quartz kitchen countertops and sintered stone islands. Its advanced "cut first, grind later" process effectively prevents chipping and damage to materials during processing, ensuring seamless bonding with no visible gaps after joining. Additionally, the equipment is simple to operate and easy to maintain, providing an effective solution for businesses to improve production efficiency and reduce labor costs.

In summary, the Yongtao Stone Chamfering Machine is a professional stone processing machine that integrates precision 45-degree chamfering with functions such as chamfering with head and tail retention. Whether chamfering large stone slabs or processing small marble pieces, Yongtao Machinery meets customers' processing needs, injecting new momentum into the production and development of stone processing enterprises.

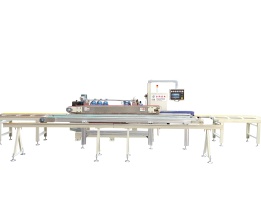

YSMDK-3200-D 7-Head Stone 45-Degree Chamfering Machine

The Yongtao 7-Head Stone 45-Degree Chamfering Machine is an efficient stone processing machine independently developed by the company. Featuring an upper and lower belt conveyor and an assembly line design, this equipment is specifically designed for complex processes such as 45-degree chamfering and grooving of sintered stone, marble, and quartz stone. It also offers automatic front and rear cham...

YSMDK-3200-D 7-Head Stone 45-Degree Chamfering Machine

The Yongtao 7-Head Stone 45-Degree Chamfering Machine is an efficient stone processing machine independently developed by the company. Featuring an upper and lower belt conveyor and an assembly line design, this equipment is specifically designed for complex processes such as 45-degree chamfering and grooving of sintered stone, marble, and quartz stone. It also offers automatic front and rear cham...

YSMDP-800 1+2+8 Stone Bevel Edge Polishing Machine

YSMDP-800 1+2+8 Stone Bevel Edge Polishing Machine is the latest product by Yongtao machinery for 45 degree edge chamfer and polishing. The machine have one squaring wheel, two 45 degree chamfer wheels and eight 45 degree polishing wheels. It can process marble, granite, artificial stone, quartz etc. The squaring wheel and chamfer wheel use diamond material. The polishing head use air cylinder, po...

YSMDP-800 1+2+8 Stone Bevel Edge Polishing Machine

YSMDP-800 1+2+8 Stone Bevel Edge Polishing Machine is the latest product by Yongtao machinery for 45 degree edge chamfer and polishing. The machine have one squaring wheel, two 45 degree chamfer wheels and eight 45 degree polishing wheels. It can process marble, granite, artificial stone, quartz etc. The squaring wheel and chamfer wheel use diamond material. The polishing head use air cylinder, po...

YSMDP-800 (1+6)-(2+6) Stone Flat Bevel Edge Polishing Machine

YSMDP-800 (1+6)-(2+6) Stone Flat Bevel Edge Polishing Machine,The stone flat and bevel edge polishing machine is one of the latest horizontal stone polishing machine by Yongtao machinery. The machine can process artificial stone, marble, granite, quartz etc. It has 1 piece 1 diamond grind wheel and 6 pieces polishing wheel to polish flat edge. At the behind of machine has 2 pieces of 45 degree cha...

YSMDP-800 (1+6)-(2+6) Stone Flat Bevel Edge Polishing Machine

YSMDP-800 (1+6)-(2+6) Stone Flat Bevel Edge Polishing Machine,The stone flat and bevel edge polishing machine is one of the latest horizontal stone polishing machine by Yongtao machinery. The machine can process artificial stone, marble, granite, quartz etc. It has 1 piece 1 diamond grind wheel and 6 pieces polishing wheel to polish flat edge. At the behind of machine has 2 pieces of 45 degree cha...

YSMDP-800 1+6-1+2 Stone Flat Bevel Edge Polishing Machine

YSMDP-800 1+6-1+2 Stone Flat Bevel Edge Polishing Machine,this machine is applied to process the flat edge and bevel edge for the marble, granite stone slabs. Put the slab on the conveyor belt, the conveyor will drive the material into working area. There are 1 flat squaring head, and 6 flat polishing heads and 2 pneumatic chamfer heads. The machine can do flat polishing and chamfer in one time. M...

YSMDP-800 1+6-1+2 Stone Flat Bevel Edge Polishing Machine

YSMDP-800 1+6-1+2 Stone Flat Bevel Edge Polishing Machine,this machine is applied to process the flat edge and bevel edge for the marble, granite stone slabs. Put the slab on the conveyor belt, the conveyor will drive the material into working area. There are 1 flat squaring head, and 6 flat polishing heads and 2 pneumatic chamfer heads. The machine can do flat polishing and chamfer in one time. M...

YSMD 11 Head Automatic Granite Flat Bevel Edge Polishing Machine

YSMD 11 Head Automatic Granite Flat Bevel Edge Polishing Machine,This machine is one of the latest models of YONGTAO Machinery.The machine is mainly used to process all kinds of single or double thick slab for flat edge, bevel edge, chamfer. It rely on the polished surface to locate, solving the problem of unevenness chamfering since different thickness. The polishing head adopt snail buckle and p...

YSMD 11 Head Automatic Granite Flat Bevel Edge Polishing Machine

YSMD 11 Head Automatic Granite Flat Bevel Edge Polishing Machine,This machine is one of the latest models of YONGTAO Machinery.The machine is mainly used to process all kinds of single or double thick slab for flat edge, bevel edge, chamfer. It rely on the polished surface to locate, solving the problem of unevenness chamfering since different thickness. The polishing head adopt snail buckle and p...