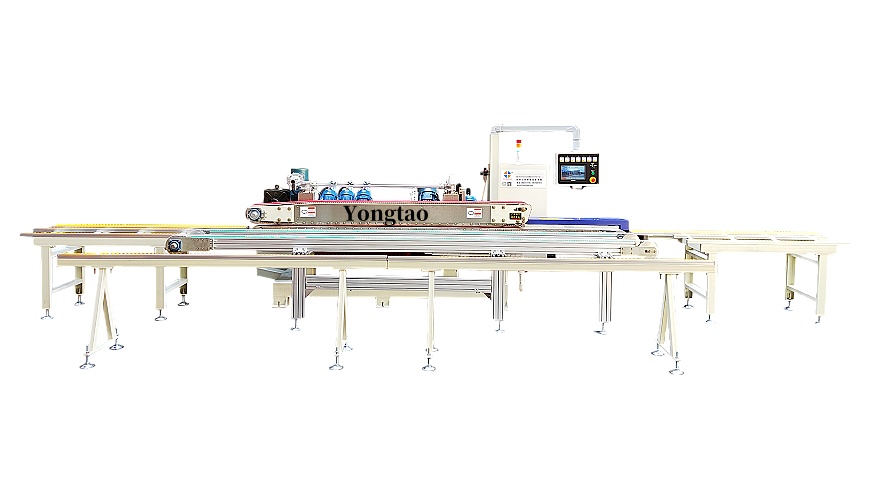

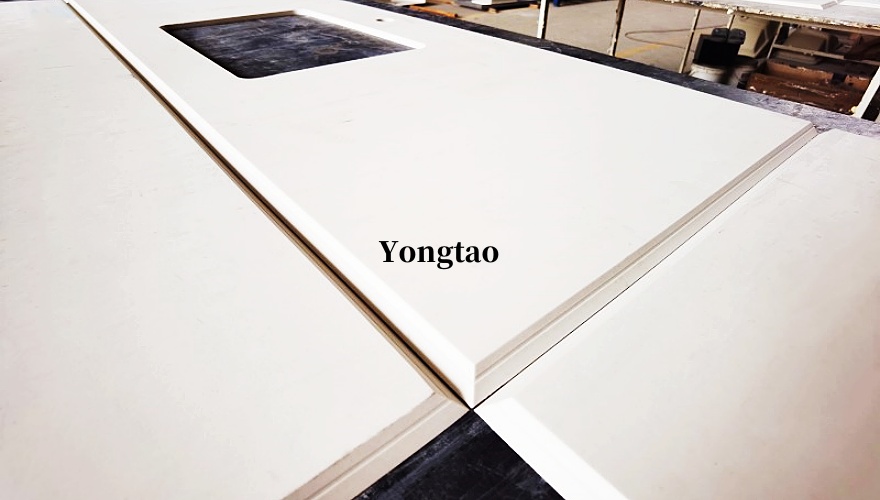

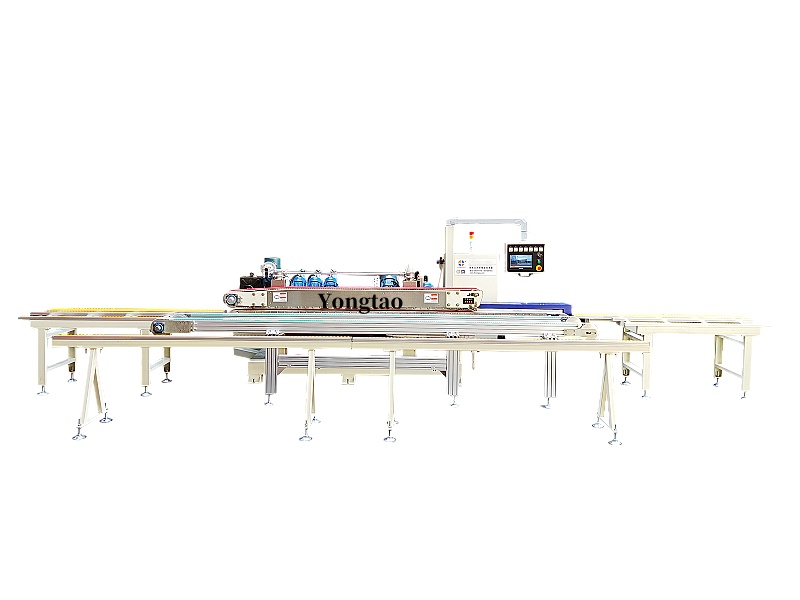

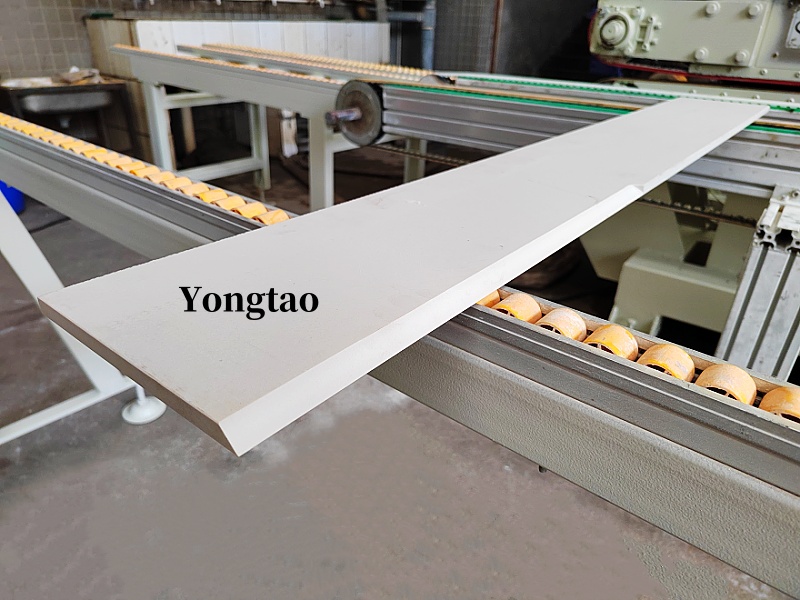

The Yongtao 7-Head Stone 45-Degree Chamfering Machine is an efficient stone processing machine independently developed by the company. Featuring an upper and lower belt conveyor and an assembly line design, this equipment is specifically designed for complex processes such as 45-degree chamfering and grooving of sintered stone, marble, and quartz stone. It also offers automatic front and rear chamfering with margin retention. This stone chamfering machine is especially suitable for processing sintered stone and quartz stone kitchen countertops and is a pioneering product in the industry. It effectively addresses the difficulties of the 45-degree chamfering process, such as low efficiency and high processing costs, providing users with a high-efficiency and precise processing experience.

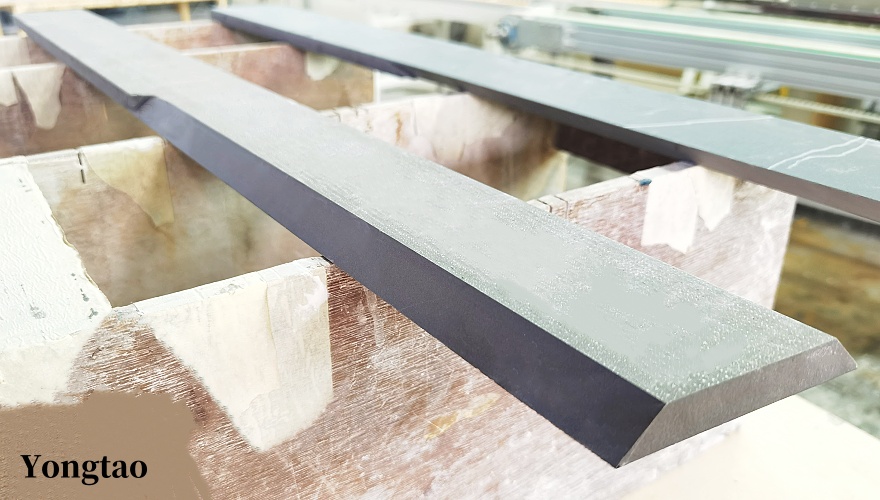

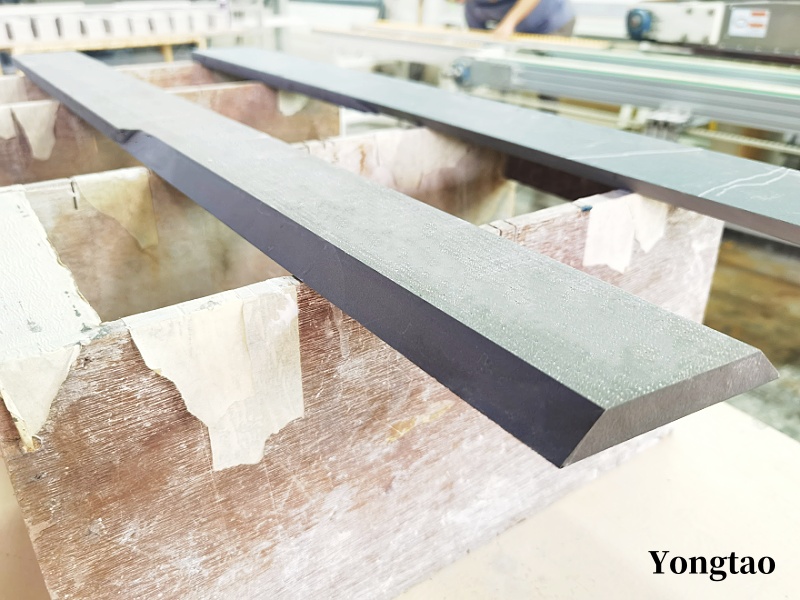

The upper and lower pressure beams of the Yongtao Marble 45-Degree Chamfering Machine are made of solid 45# steel and undergo annealing heat treatment. Combined with a high-strength synchronous belt transmission design, this ensures machining accuracy and stability during material conveyance. The equipment utilizes an advanced cut-then-grind processing method, equipped with high-power, high-speed motors to efficiently complete six processes, including rough grinding, fine grinding, and grooving, all in one go, significantly improving production efficiency. The quartz stone 45-degree chamfering machine also features multiple functions such as pre-cutting, cutting, grooving, trimming, and chamfering, with three 45-degree chamfering heads that enable fast and precise processing, enhancing machining accuracy and product quality.

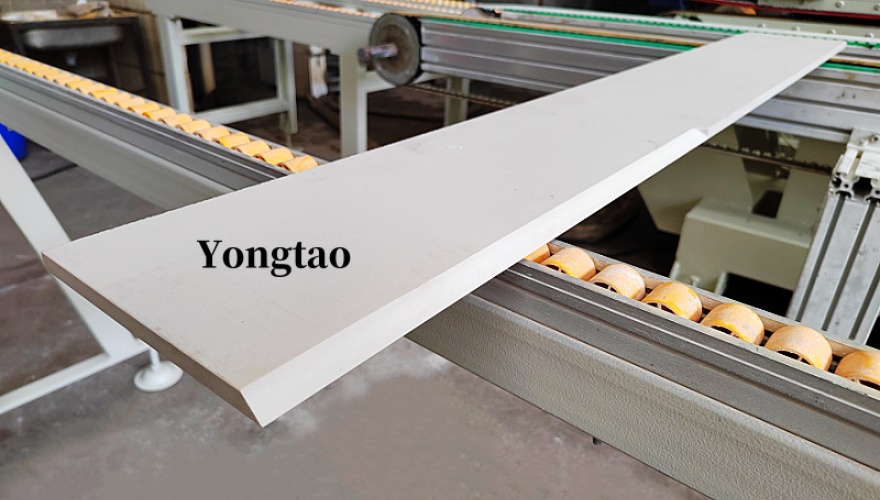

This 45-degree stone cutting machine is designed with multiple functionalities, capable of pre-cutting, cutting, grooving, and trimming, meeting various processing needs. The equipment features a belt conveyor structure, solid carbon steel upper and lower pressure beams, and overall annealing heat treatment to ensure machining precision and stability. The PLC control system uses the Japanese Omron brand, ensuring stable and reliable operation. The support frame for the quartz stone chamfering machine is made of aluminum alloy, which is easy to install, durable, and cost-effective.

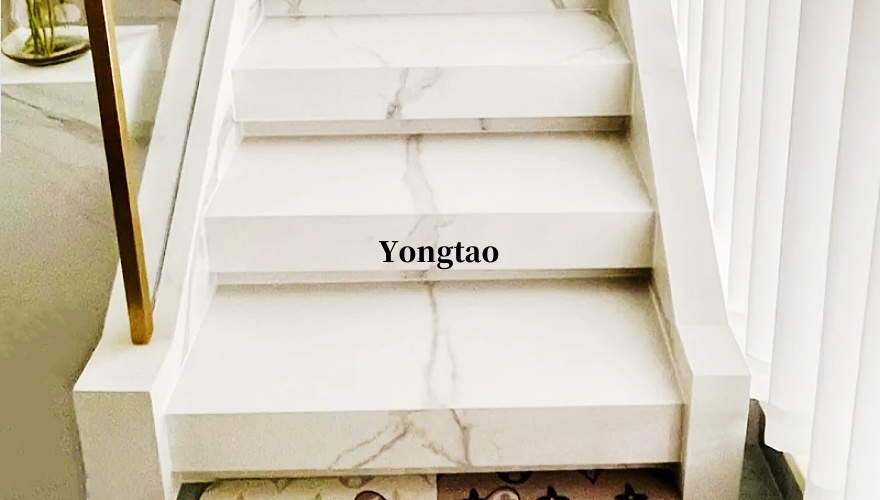

The 45-degree quartz stone cutting machine not only offers significant advantages in processing efficiency but also excels in economic benefits. The processing cost per meter is approximately 0.45 RMB, effectively improving production efficiency and economic returns. The equipment can adjust the chamfering angle to 44.8 or 45 degrees according to customer requirements, with grooves on the beveled edge to enhance adhesive bonding, ensuring that the processed stone, marble, and sintered stone are beautiful, durable, and long-lasting. Additionally, the dual-saw blade cutting speed for quartz stone is faster, significantly reducing processing time.

The marble chamfering machine features a thickness limit function and automatic protection for the pressure beam's lifting and lowering, effectively preventing misoperation and improving equipment safety and stability while reducing maintenance costs. The minimum processing size is 30mm, and the maximum size can reach up to 3.8 meters, meeting the chamfering needs of different stone sizes. The user-friendly interface allows for simple operation with one-click start, reducing equipment operation difficulty and personnel training costs.

In summary, the Yongtao 7-Head Stone 45-Degree Chamfering Machine offers high precision, multi-functionality, excellent stability, and durability, making it an outstanding product in the field of stone processing machinery. It not only meets users' diverse processing needs for stone, quartz stone, marble, and other materials but also performs exceptionally well in improving production efficiency and reducing processing costs. This 45-degree marble cutting and stone chamfering machine is highly recommended, creating greater economic benefits and value for users.

Technical Parameters:

Name | Technical Parameter | Name | Technical Parameter |

Number of Cutting Motors | 2 | Power of 45-Degree Chamfering Motor | 2.2kw |

Power of Pre-cutting Motor | 3kw | Size of 45-Degree Chamfering Wheel | Φ150x12x6mm |

Size of Pre-cutting Blade | Φ210x60mm | Size of Belt | 100mm |

Power of 45-Degree Cutting Motor | 7.5kw | Inlet | 50mm |

Size of 45-Degree Cutting Blade | Φ310x50mm | Processing Size | 3200mm |

Number of Slotting Motors | 1 | Processing Thickness | 3 - 20mm |

Power of Slotting Motor | 2.2kw | Processing Speed | 0.5-2m/min |

Size of Slotting Blade | Φ210x60mm | Minimum Processing Size | 30mm |

Number of Trimming Motors | 1 | Total Power | 24.87kw |

Power of Trimming Motor | 2.2kw | Mechanical Dimensions | 4.3x(1.3-2.2)x1.85m |

Size of Trimming Wheel | Φ150x12*10mm | Dimensions of Front and Rear Shelves | 1.9x0.6x0.8m |

Number of 45-Degree Chamfering Heads | 3 | Weight | About 3500kg |

[email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China