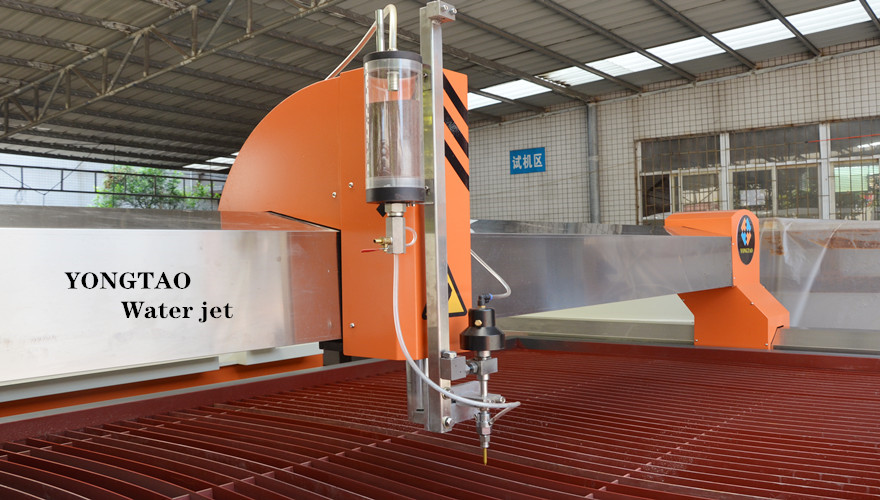

The YJ-4020-3L 3-Axis Water Jet Glass Cutting Machine from the YONGTAO brand is a high-precision cutting device made in Foshan, Guangdong, China. It is designed to handle a variety of materials, including stone, marble, granite, quartz, glass, metals, stainless steel, steel plates, alloy steel, ceramic tiles, and aluminum. With its robust structure and advanced precision, this machine is ideal for large-scale cutting tasks, especially where vertical cutting is required, making it an excellent glass water jet cutting machine for sale in industrial applications.

The Water jet glass cutting machine adopts a 3-axis gantry configuration, comprising a crossbeam and dual support structures to maintain operational stability. With X, Y, and Z-axis movement, this machine handles diverse materials such as stainless steel, glass, aluminum, and rubber. Its water-cooled cutting technology prevents heat effects, ensuring eco-friendliness and precision for delicate materials. The waterjet glass cutting machine produces smooth edges without slag, reducing the need for post-processing and enhancing production efficiency.

Constructed for long-term performance, this machine includes durable chain drives and high-quality sensors to provide consistent and stable operations. It features a labyrinth-style waterproof and sandproof rail system with dual protective curtains, extending the equipment’s lifespan. The stainless-steel protective cover prevents dust, water, rust, and corrosion, ensuring easy cleaning. Integrated with servo drive technology, the Water jet glass cutter achieves smooth, gap-free movement with high-precision ball screws and linear guides.

As one of the best water jet machines available, it comes fully equipped with a cutting table, CNC water jet control system, abrasive feeding mechanism, ultra-high-pressure booster, and recirculating cooling tower. This setup maximizes efficiency in complex processing environments, particularly for multi-curve cutting projects. With CAD software compatibility, users can execute intricate cuts accurately and efficiently. Its unique sand valve design supports smooth abrasive flow, lowering maintenance frequency and boosting productivity.

This Water jet glass cutting machine is highly capable, offering a maximum cutting thickness of 40mm for metals and up to 50mm for materials like glass, stone, and ceramics. It accommodates a maximum cutting dimension of 4000mm x 2000mm with an accuracy of ±0.1mm. Key specifications include a gem nozzle diameter of 0.33mm, a sand nozzle of 1.0mm, a maximum flow rate of 11.1 l/min, and a maximum abrasive consumption of 190 g/min. The machine has a Z-axis travel range of 130mm, maximum pressure of 420Mpa, operating pressures between 300-380Mpa, main motor power of 30kW, and total power output of 37kW, supporting AutoCAD for high-precision tasks.

For those looking to buy a water jet machine, this model's packaging dimensions include: a cutting table of 5.1m x 3.2m x 1.65m, a booster system of 1.3m x 0.95m x 1.25m, an abrasive feeder of 0.6m x 0.6m x 0.95m, and a control system of 0.65m x 0.65m x 1.67m. Widely used across stone processing, metal cutting, and construction, this Water jet glass cutting machine meets the precision requirements for various industries, providing efficient and eco-friendly solutions.

Technical parameters:

Model | YJ-4020-3L | |

Structure | Bridge | |

Cutting table size | 4100x2100mm | |

Stroke | X-axis | 4000mm |

Y-axis | 2000mm | |

Z-axis | 130mm | |

CNC Controller | AC Servo System | |

Accuracy | Cutting | ±0.1mm |

Repeat ability | ±0.05mm | |

Traverse speed | 6000/15000 mm/min | |

Power source | 380VAC, 50Hz, 3Phase | |

[email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China