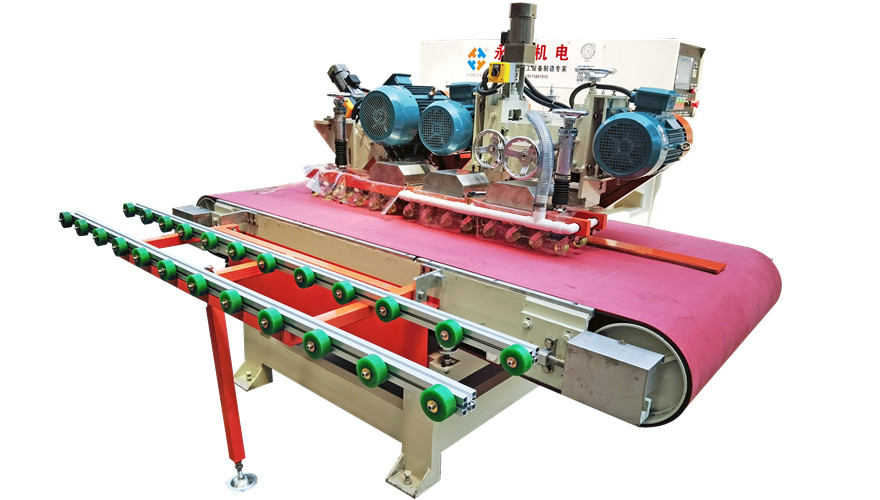

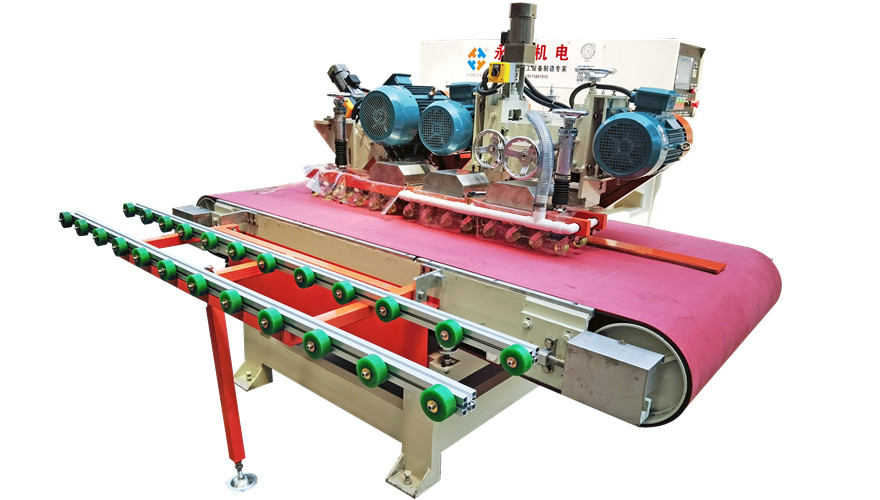

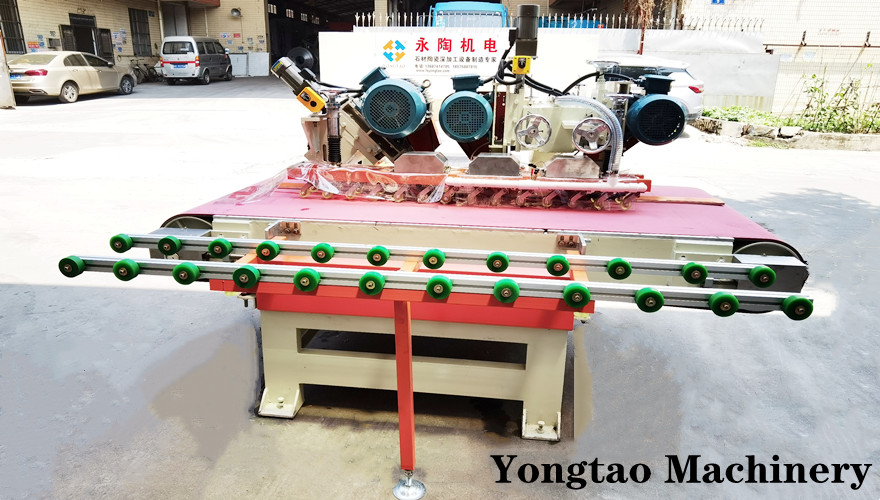

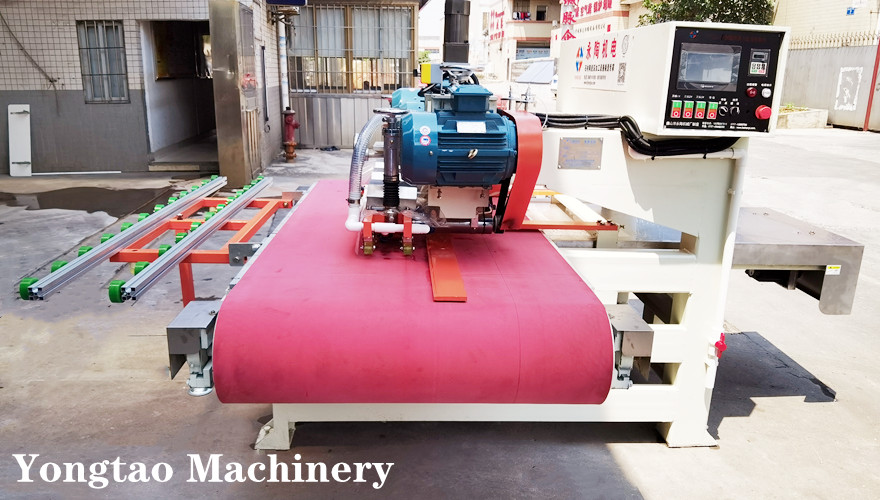

YTQZ-A/3-1800 Three Blade CNC Sintered Stone Cutting Machine is Yongtao machinery in combination with the demand of the market, research and development production of a large size sintered stone cutting machine. It can cut a piece of 900 * 1800 mm sintered stone into 900 * 900 mm or 450 * 1800 mm, cutting size can be set in the numerical control which display the cutting size. The cutting precision can be controlled within 0.1 mm. It can cut a variety of specifications and quickly switch cutting size. 1200 * 2700/2800 mm half-and-half cut is no problem, and quick in cutting speed, cutting good stability, no change Angle of cutting edge won't crack, no head size. Cutting blades adopt (Φ120-130mm ) * 20 mm of small specifications of the blade. Because small blade cheap, low processing cost. It has a simple operation, very convenient. Numerous advantages of high cutting precision, has been accepted by the masses of customers to use in China, was deeply loved by customers. At the same time can be customized for clients a variety of special type sintered stone cutting machine, meet the use of a variety of customer needs. Yongtao machinery in China is the earliest developed a full range of sintered stone machinery manufacturers, products involved in sintered stone cutting machine, CNC sintered stone polishing machine, sintered stone 45 degrees polishing machine, sintered stone arc edge polishing machine, AC 5 axis water Jet cutting machine and other sintered stone machines. If you purchase sintered stone machinery, Yongtao machinery can meet your one-stop purchase needs, solve your worries, let you buy at ease, a big enterprise, trustworthy, a real customer to solve the problem of the manufacturer, is your first choice to buy the brand.

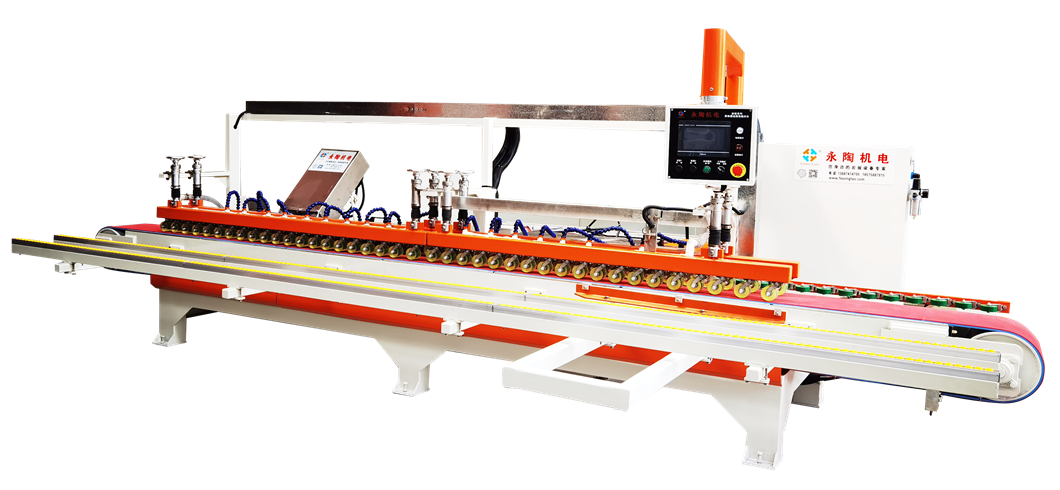

Three Blade CNC Ceramic Cutting Machine:

CNC Sintered stone cutting machine:

Cutting materials: ceramic tile, artificial stone, quartz stone, sintered stone

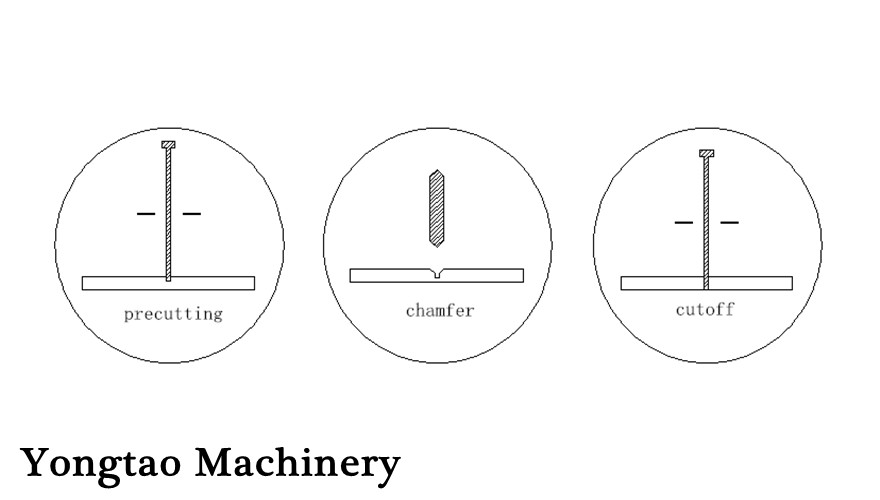

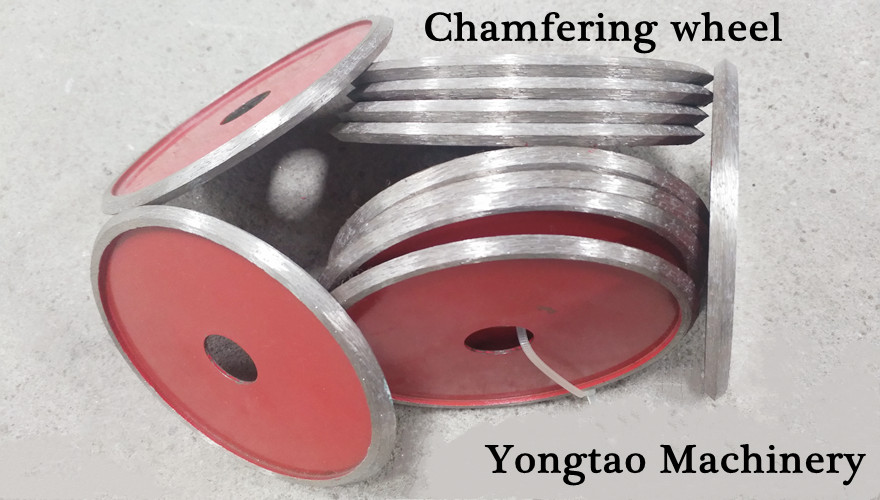

Equipment functions: cutting and sharpening (using V-shaped wheel)

Sintered stone cutting machine Mechanical equipment features:

1, CNC size adjustment, high precision cutting, fast;

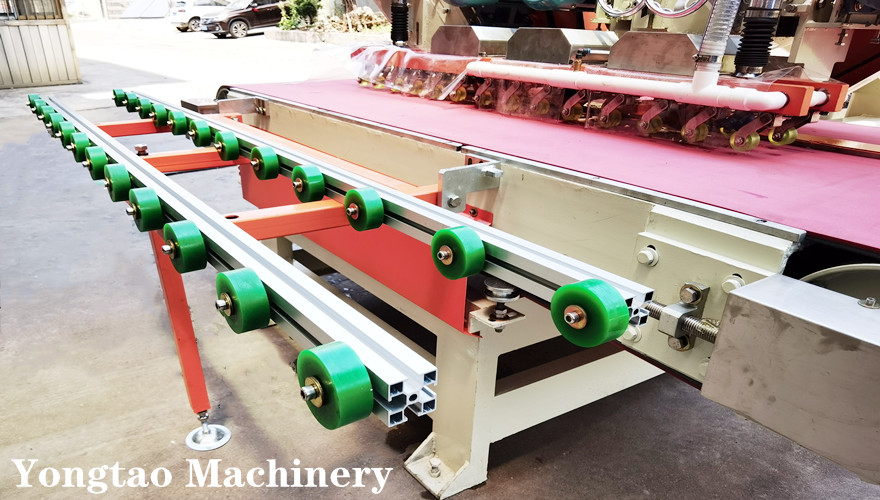

2, manually adjust the lifting height, up and down cutting depth can be controlled by themselves;

3, the maximum cutting width size is 1800mm, half cutting, cutting length is not limited;

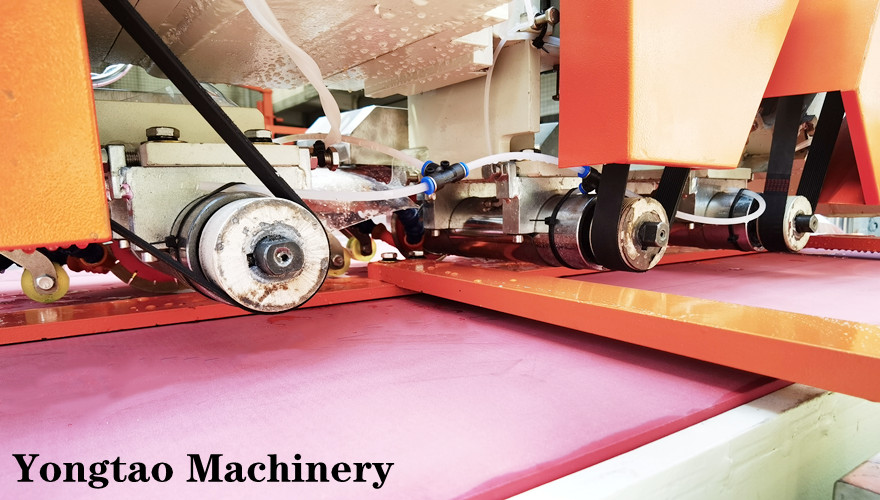

4, the front of a blade cut half, second blade in the middle to process the surface of the left and right sharp edge, the last blade cut off

5. The distance between the middle cutting blade and the back cutting blade is close, which can effectively avoid cutting off the corner and achieve good cutting effect.

6. The main drive belt uses red double-layer belt, and the upper layer is red soft material, which can be cut at will;

7, the outside of the supporting brick mechanism can be freely telescopic, cutting large specifications of the plate, the supporting brick mechanism plays the role of balance plate;

8. Stainless steel water cover is used around the machine, which is beautiful and atmospheric and prevents sewage from flowing everywhere;

9, 4 rows of brick pressing mechanism is the use of small pressure wheel brick, can cut smaller size;

10, baffle screw using precision oil bubble screw, left and right two sliders in and out of sync, will not appear the phenomenon of cutting size deviation.

Automatic Tile Cutting Machine Parameter:

No. | Name | Parameter |

1 | Cutting head | 2pcs |

2 | Trimming head | 1个 |

3 | Max cutting width (one into two) | 1800*900mm |

4 | CNC adjust width | 0-900mm |

5 | Processing thickness | 6-20mm |

6 | Cutting speed | 0-5.0m/min |

7 | Total power | 17.61kw |

8 | Water consumption | 350L/min |

9 | Size of machine | 3000x2850x1720mm |

10 | weight | About 2000kg |

11 | Voltage | 380V, (415V can be customized) |

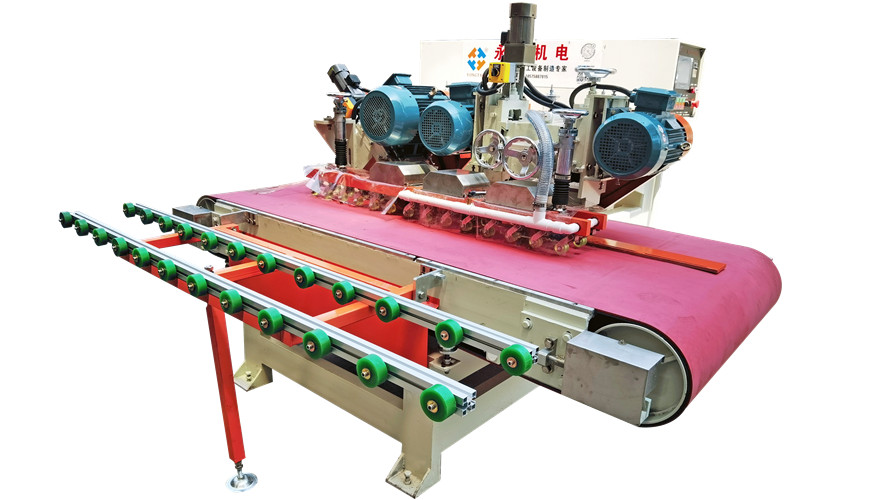

YAMDP-250 1+8+2+2 Small Size Sintered Stone Flat Bevel Edge Polishing Machine

YAMDP-250 1+8+2+2 Small Size Sintered Stone Flat Bevel Edge Polishing Machine

YAQZ-2000 CNC Sintered Stone Cutting Machine

YAQZ-2000 CNC Sintered Stone Cutting Machine

YAQZ-3200 3 Axis Bridge Type CNC Sintered Stone Cutting Machine

YAQZ-3200 3 Axis Bridge Type CNC Sintered Stone Cutting Machine

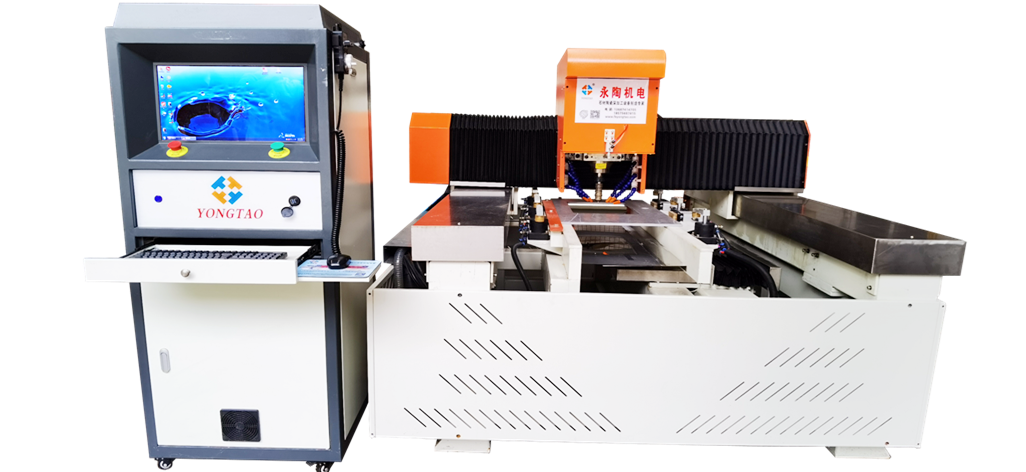

YANMP-1300 CNC Sintered Stone Basin Hole Edge Polishing Machine

YANMP-1300 CNC Sintered Stone Basin Hole Edge Polishing Machine

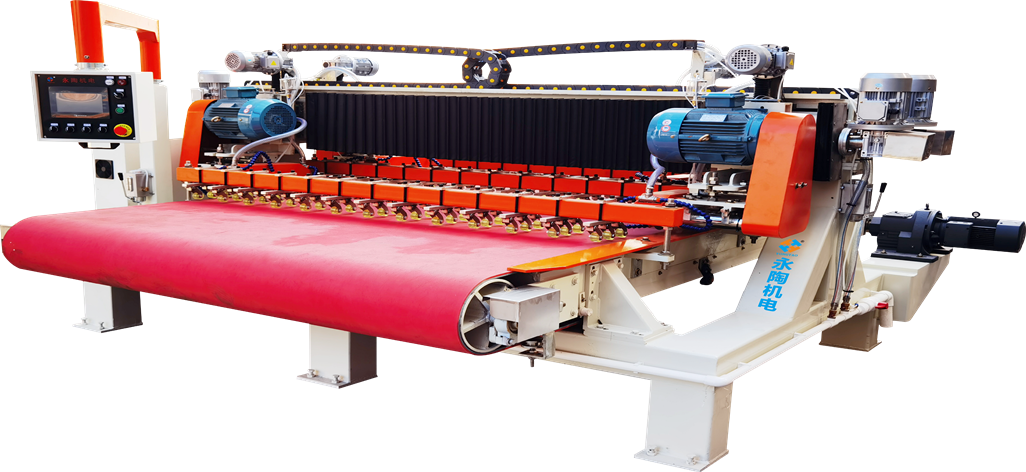

YAMDP-1800 1+12+2+2 Sintered Stone Straight Edge Polishing Machine

YAMDP-1800 1+12+2+2 Sintered Stone Straight Edge Polishing Machine

[email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China