There are two kinds of stone line processing machines from the processing products:

1. Processing capacity is not very large; there are many varieties

2. Large processing capacity; with not many shapes; suitable for mass production

stone line processing machine from the mechanical point of view, which machine is suitable for processing output:

1. A small amount of processing, it is recommended to buy a stone line copying machine

2. A large amount of processing, it is recommended to buy automatic stone line machine

Comparison of daily processing output between automatic stone line machine and stone profiling machine:

1. Automatic stone line processing machine daily processing output can reach 200-300 meters (8 hours), good processing effect, no silk, good handle, neat seams, brightness up to 90-120 degrees, no need to wax, no knife, processing speed is fast.

2. The daily processing output of the stone copying machine is about 30-50 meters, which is only rough grinding. It also needs manual polishing, waxing, uneven joints, dark brightness, no glossiness, low output, and high labor cost.

3. The daily processing output of the stone bridge edge grinding machine is about 60-100 meters. Due to the operation of one grinding wheel, the grinding wheel needs to be replaced several times. In this case, the grinding wheel is replaced frequently, which wastes a lot of labor time, and the processing capacity can not be raised. If you want to process fast, you need to buy several more stone bridge edge grinding machines, one for grinding shape, one for rough polishing and one for fine polishing, At least three machines are required to process at the same time. The processing speed is faster when the grinding wheel is not always replaced. In this case, it is better to buy an automatic stone line polishing machine. Moreover, the final processing effect is not as good as that of the automatic stone line processing machine. The output is not as large as that of the automatic stone line processing machine, and several workers are required to operate it, It's cost-effective to buy this kind of machine without buying an automatic stone line processing machine.

Automatic stone line processing machine can be divided into:

1. Stone molding machine

3. All in one machine for shaping and polishing stone lines

Stone line shaping machine (for line modeling) can be divided into:

1. 4-head stone line shaping machine

2. 5-Head stone line shaping machine

3. 6-head stone line shaping machine

Stone line shaping and polishing integrated machine can be divided into:

1. 3 + 5 stone line processing machine (3 head shaping, 5 head polishing)

2. 4 + 4 stone line processing machine (4 head shaping, 4 head polishing)

3. 3 + 6 stone line processing machine (3 head shaping, 6 head polishing)

4. 3 + 7 stone line processing machine (3 shaping, 7 polishing)

5. 4 + 6 stone line processing machine (4 shaping, 6 polishing)

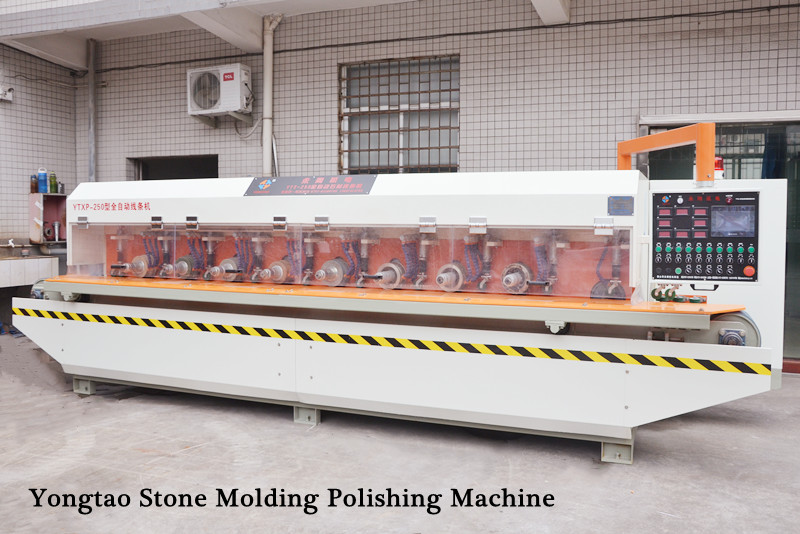

Stone line polishing machine (pure polishing) can be divided into:

1. 6-head stone line polishing machine

2. 8-head stone line polishing machine

3. 9-head stone line polishing machine

The automatic stone line polishing line can be divided into:

1. 4 + 8 (12 heads) automatic stone line polishing machine (1 set for 4-head shaping and 1 set for 8-head polishing)

2. 5 + 8 (13 heads) automatic stone line polishing machine (1 set for 5-Head shaping and 1 set for 8-head polishing)

3. 6 + 8 (14 heads) automatic stone line polishing machine (1 set for 6 heads and 1 set for 8 heads polishing)

4. 4 + 6 (10 heads) automatic stone line polishing machine (1 set for 4-head shaping and 1 set for 6-head polishing)

5. 4 + 7 (11 heads) full automatic stone line polishing machine (1 set for 4-head shaping and 1 set for 7-head polishing)

For small stone processing plant, it is suggested to select 8-head (3 + 5) stone line processing machine

For the selection of batch processing stone line: 12 head (4 + 8) stone line processing machine

If processing natural marble lines, it is recommended to use 12 head (4 + 8) automatic stone line processing machine. Because the marble lines are brittle and have cracks, it is necessary to polish the lines by adding glue and polishing them with a polishing machine. In this way, the processing effect will not be affected and the processing speed will be fast.

It is recommended to consult the manufacturer by telephone first to know in detail what kind of material to process, how much to produce per day, and what kind of configuration to choose. This is the most suitable stone processing machine for you.

[email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China