Yongtao water jet cutting machine integrates pumps, valves, seals, hydraulic pressure, and automatic control. It is composed of high-pressure pumps, processing platforms, jet cutting heads, transmission systems, and switch water control systems. It is a cold cutting technology with applicable It has the characteristics of wide range, good cutting surface, no deformation during processing, clean and environmental protection, etc.

In terms of working principle, the water jet cutting machine uses the principle of liquid pressurization. Through a specific energy transfer device (supercharger or high-pressure pump), the mechanical energy of the motor is converted into the pressure energy of water and is ejected through the small hole nozzle. The pressure energy is converted into kinetic energy to form a high-speed water jet for workpiece processing.

The specific application principle is as follows:

1. When the water jet cutting machine is working, the high-pressure water pump as the power source of the water jet uses a hydraulic motor to forcibly compress tap water or deionized water, so that the pressure of the water increases to tens to hundreds of MPa, and the flow rate reaches 6L/min. It has the corresponding cutting efficiency and the energy required for cutting.

2. When the water column is ejected through the beam nozzle, a high-speed water jet is formed under high pressure and kinetic energy, that is, a "water jet" with great kinetic energy. According to different workpiece materials, such as ceramics, stone, glass, metal, alloy, etc., a certain proportion of abrasives can also be mixed in high-speed water flow to provide stronger penetration.

3. Finally, under the control of the CNC precision system, the processing platform performs one-way or two-way linkage of the X-axis and Y-axis to drive the water jet cutting machine to realize functions such as straight line or curve cutting and descaling cleaning on the workpiece to be processed. Flexible and accurate operation.

It is worth noting that the size of the nozzle aperture of the water jet cutting machine determines the pressure level and the flow rate. You can debug it according to the specific application environment, and the water jet cutting machine also relies on its strong cutting performance and processing accuracy. Efficiency, in various It is widely used in various fields and materials.

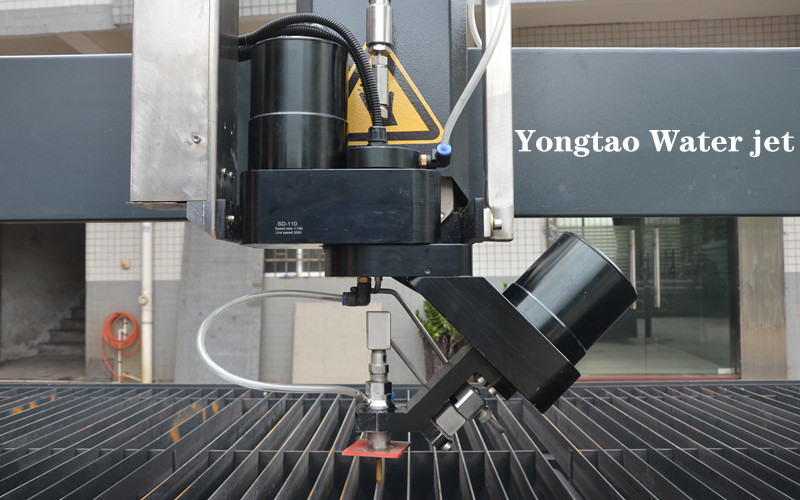

The water jet cutting machine is mainly composed of four parts:

high pressure pump, cutting head, transmission system and control system.

High-pressure pump:

The high-pressure pump of the water jet cutting machine adopts hydraulic boosting technology to increase the pressure of water to a very high level. Common high-pressure pumps include plunger pumps and plunger diaphragm pumps.

Cutting head:

The cutting head of a waterjet cutting machine usually contains a nozzle, an abrasive nozzle and a mixing chamber. Nozzles are used to create high-speed water streams, while abrasive nozzles are used to mix abrasives to increase cutting power. The mixing chamber is used to mix water and abrasive.

Transmission system:

The transmission system consists of high-pressure hose and transmission pipes to transmit high-pressure water flow from the pump to the cutting head. During the transmission process, shock absorbers and mufflers also need to be installed to avoid the impact of pressure waves on the pipeline.

Control system:

The control system of the water jet cutting machine is mainly composed of numerical control system and hydraulic control system. The CNC system can control the movement of the processing platform to realize automatic processing, while the hydraulic control system is used to control the working status of the high-pressure pump and cutting head.

In general, a water jet cutting machine achieves the cutting of the workpiece by increasing the pressure of water to a very high level and forming a high-speed water flow through the nozzle. In practical applications, water jet cutting machines have the advantages of high precision, low energy consumption, and environmental protection, and are widely used in the processing of various materials.

[email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China