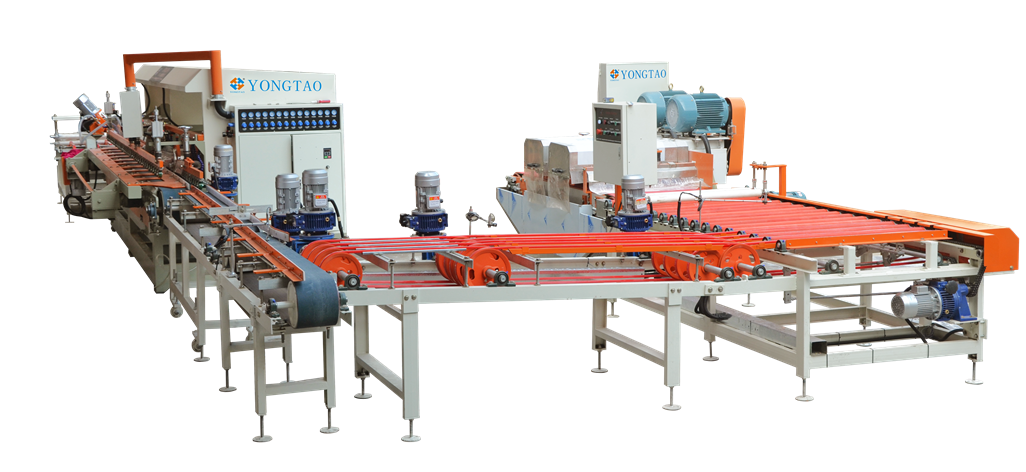

Yongtao Machinery has developed this ceramic tile chamfering machine based on the specific needs of its customers. The machine is equipped with one rough grinding head, two 45-degree chamfering heads, one chamfering head for the backside of the tile, and six 45-degree polishing heads, ensuring high-precision tile processing.

The machine allows for adjusting the chamfer depth according to processing requirements. Options include 1/4 bevel, 1/2 bevel, 3/4 bevel, and 1/3 bevel, providing flexibility in ceramic tile beveling machine operations for various types of bevel edges.

The rough grinding and chamfering stages use diamond grinding wheels to remove excess material and achieve the desired 45-degree angle. Afterward, the polishing heads work to perfect the finish, making this tile chamfering machine highly efficient in producing smooth and precise results.

Yongtao Machinery offers a range of tile beveling machine models and can also customize a ceramic tile bevel polishing machine tailored to your specific requirements, ensuring that all your tile processing needs are met with precision and reliability.

Marble Flat Bevel Edge Polisher

10 30,2019

Marble Flat Bevel Edge Polisher

VIEW

Marble Flat Bevel Edge Polisher

10 30,2019

Marble Flat Bevel Edge Polisher

VIEW YTQS-2-1200 Manual Multifunctional Tile Cutting Machine

11 04,2019

YTQS-2-1200 Manual Multifunctional Tile Cutting Machine

VIEW

YTQS-2-1200 Manual Multifunctional Tile Cutting Machine

11 04,2019

YTQS-2-1200 Manual Multifunctional Tile Cutting Machine

VIEW YTH-800 Dry Ceramic Tile Cutter

10 30,2019

YTH-800 Dry Ceramic Tile Cutter

VIEW

YTH-800 Dry Ceramic Tile Cutter

10 30,2019

YTH-800 Dry Ceramic Tile Cutter

VIEW YTQZ-B/2-800 Double Spindle Multi Saw Blade Tile Cutting Machine

04 02,2019

YTQZ-B/2-800 Double Spindle Multi Saw Blade Tile Cutting Machine,This is two spindle tile cutting machine,it is specialized to cut tile strips.It can install 7-8 blades on each spindle,which can cut the tile into several strips in one time.For example, cu

VIEW

YTQZ-B/2-800 Double Spindle Multi Saw Blade Tile Cutting Machine

04 02,2019

YTQZ-B/2-800 Double Spindle Multi Saw Blade Tile Cutting Machine,This is two spindle tile cutting machine,it is specialized to cut tile strips.It can install 7-8 blades on each spindle,which can cut the tile into several strips in one time.For example, cu

VIEW YTYP-1200/7+14 Porcelain Tile Bullnose Machine

04 02,2019

YTYP-1200/7+14 Porcelain Tile Bullnose Machine,The ceramic tile bullnose machine is applied to the deep processing of ceramics, for example: edging, chamfering (30 degree,45 degree, 60 degree), bottom chamfering, grinding bullnose, polishing (bull

VIEW

YTYP-1200/7+14 Porcelain Tile Bullnose Machine

04 02,2019

YTYP-1200/7+14 Porcelain Tile Bullnose Machine,The ceramic tile bullnose machine is applied to the deep processing of ceramics, for example: edging, chamfering (30 degree,45 degree, 60 degree), bottom chamfering, grinding bullnose, polishing (bull

VIEW YTQZYP-1000 Two Spindle Ceramic Cutting And Tile Bullnose Polishing Machine

05 29,2019

YTQZYP-1000 Two Spindle Ceramic Cutting Machine And Ceramic Tile Bullnose Polishing Machine,Two spindle tile cutting machine can install multiple blades on each of spindle. It can cut several tile strips in one time. The max cutting size of this two spind

VIEW

YTQZYP-1000 Two Spindle Ceramic Cutting And Tile Bullnose Polishing Machine

05 29,2019

YTQZYP-1000 Two Spindle Ceramic Cutting Machine And Ceramic Tile Bullnose Polishing Machine,Two spindle tile cutting machine can install multiple blades on each of spindle. It can cut several tile strips in one time. The max cutting size of this two spind

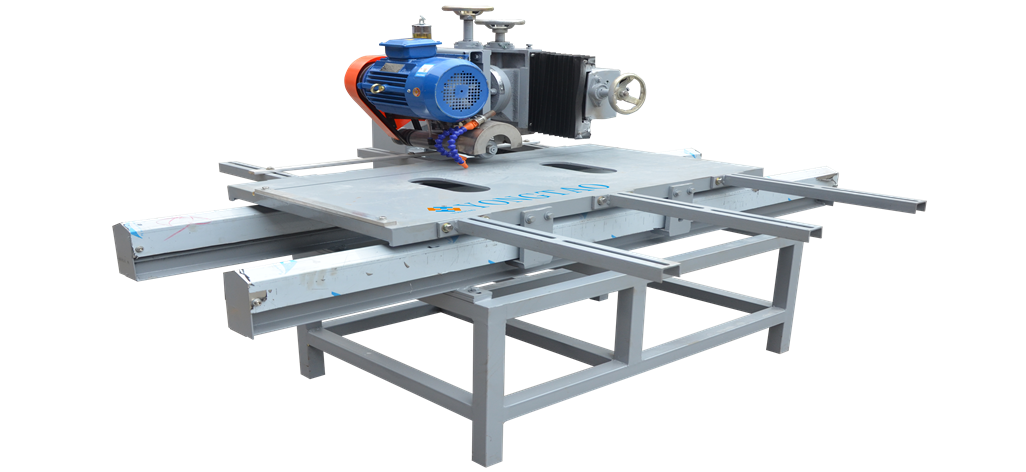

VIEW YTQS-2-1200 Manual Multifunctional Tile Cutting Machine

04 02,2019

YTQS-2-1200 Manual Multifunctional Tile Cutting Machine,The machine is a powerful deep processing machine for ceramic tile.It can do almost all of processing by this single one machine,such as cutting,grooving,edging,chamfering,grinding bullnose.It is

VIEW

YTQS-2-1200 Manual Multifunctional Tile Cutting Machine

04 02,2019

YTQS-2-1200 Manual Multifunctional Tile Cutting Machine,The machine is a powerful deep processing machine for ceramic tile.It can do almost all of processing by this single one machine,such as cutting,grooving,edging,chamfering,grinding bullnose.It is

VIEW YSU-1200 16 Head Stone Polishing Machine

05 24,2019

YSU-1200 16-head stone polishing machine, which can polish the surface of marble, stone, quartz stone, granite, and also can be used for the surface polishing of stone mosaics, as well as some small pieces of stone, the surface polishing treatment, the ma

VIEW

YSU-1200 16 Head Stone Polishing Machine

05 24,2019

YSU-1200 16-head stone polishing machine, which can polish the surface of marble, stone, quartz stone, granite, and also can be used for the surface polishing of stone mosaics, as well as some small pieces of stone, the surface polishing treatment, the ma

VIEW YTQZ-B/1-600 Single Spindle Tile Cutter For Mosaic Tiles

05 24,2019

Create wonderful mosaic artworks and installations with these mosaic tile cutter machines. Read on to find out more about them and how they can be useful.

VIEW

YTQZ-B/1-600 Single Spindle Tile Cutter For Mosaic Tiles

05 24,2019

Create wonderful mosaic artworks and installations with these mosaic tile cutter machines. Read on to find out more about them and how they can be useful.

VIEW 0086 18665475362

0086 18665475362  [email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China