Description of YTQZYP-1000 Two Spindle Ceramic Cutting And Tile Bullnose Polishing Machine

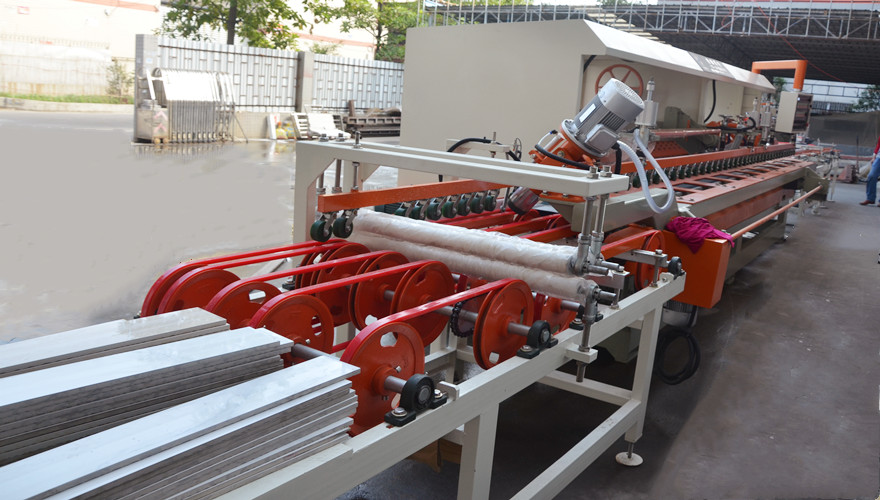

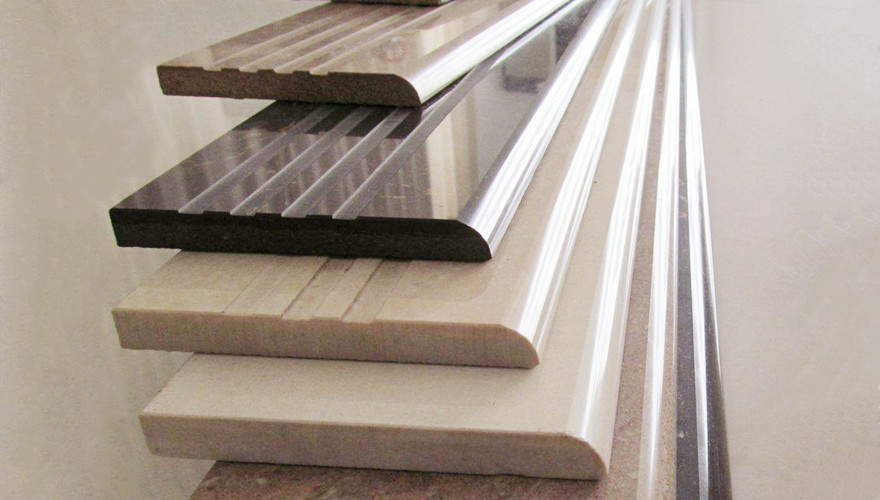

YTQZYP-1000 Two Spindle Ceramic Cutting Machine And Ceramic Tile Bullnose Polishing Machine, this two spindle tile cutting machine can install multiple blades on each of spindle. Ceramic skirting polishing machine can cut several tile strips in one time. The max cutting size of this two spindle ceramic tile cutting machine is 1000*1000mm ceramic tile. The tile strips can be processed into skirting. This production line can cut one piece tile into 3-8 pieces strips in one time, and then cross the conveyor belt to the 14 head ceramic tile bullnose machine, finally come out from the drying device. The whole production line can batch process ceramic tile skirting with fast speed. It is suit for large quantity processing of skirting factories. Put 600*600mm/800*800mm/1000*1000mm into the two spindle ceramic tile cutting machine, it can be cut into different width strips, such as 600*100mm/600*200mm/600*300mm, 800*100mm/800*200mm, 100*1000mm/200*1000mm, and other ceramic tile size specifications. It is batch processing of single specification of ceramic tile, fast, high efficiency, and can at the same time polishing two sides.

Put 600*600mm/800*800mm/1000*1000mm into the two spindle ceramic tile cutting machine, it can be cut into different width strips, such as 600*100mm/600*200mm/600*300mm, 800*100mm/800*200mm, 100*1000mm/200*1000mm, and other ceramic tile size specifications. It is batch processing of single specification of ceramic tile, fast, high efficiency, and can at the same time polishing two sides.

The wearing parts of 14 head ceramic tile bullnose machine: Y6/Y3 polishing head, plastic tape, press wheel, resin groove disc, water pipe, polishing head cup, polishing head spindle, polishing head belt, diamond grind wheel, diamond chamfer wheel, lifting cover.

The spare parts of 14 head ceramic tile bullnose machine: polishing motor, conveyor belt, control panel button, gas table, air cylinder, chamfer motor.

The spare parts of two spindle tile cutting machine: spacer, gasket, press wheel or press plate, diamond saw blade, mosaic cutting mold.

Yongtao machinery produce ceramic processing machinery, stone processing machinery, water jet cutting machine, quartz countertop processing machinery, is able to customize the machines for different requirements of clients. The machines of Yongtao have the advantage on high level of automation, saving labor cost, simple operation, high product efficient. It is popular in all of the world.

Parameter of Two Spindle ceramic cutting machine

No | Name | Parameter |

1 | Conveyor belt | 1015mm |

2 | Numbers of spindle | 2pcs |

3 | Main motor power | 15kw*2pcs |

4 | Diameter of blade | (Ø150*250)*60mm |

5 | Conveyor motor | 2.2kw |

6 | Lifting motor | 0.75kw |

7 | Max processing size | 1000*1000mm |

8 | Max Cutting thickness | 20mm |

9 | Size of machine | 2350*2100*1780mm |

10 | Weight | 1800kg |

11 | Total power | 33.7kw |

Parameter of ceramic Tile Bullnose Polishing Machine

No | Name | Parameter |

1 | Conveyor belt | 300mm |

2 | Polishing head | 14pcs |

3 | Diameter of polishing head | 95mm/Y6 |

4 | Numbers of chamfer | 6pcs |

5 | Diameter of chamfer | 150-200mm |

6 | Numbers of groove | 3-4pcs |

7 | Diameter of groove | 150mm |

8 | Pneumatic chamfer | 1pc |

9 | Diameter of pneumatic chamfer | 95mm |

10 | Drying fans | 2个 |

11 | Motor power | 3kw |

12 | Processing width | 70-1200mm |

13 | Polishing speed | 1.5-8m/min |

14 | Processing thickness | 6-20mm |

15 | Total power | 36.7KW |

16 | Electric consumption | 25KW/h |

17 | Air consumption | 50L/min |

18 | Water consumption | 490L/min |

19 | Size of machine | 7.60m*2.20m*1.8m |

20 | Weight | 约5800kg |

[email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China