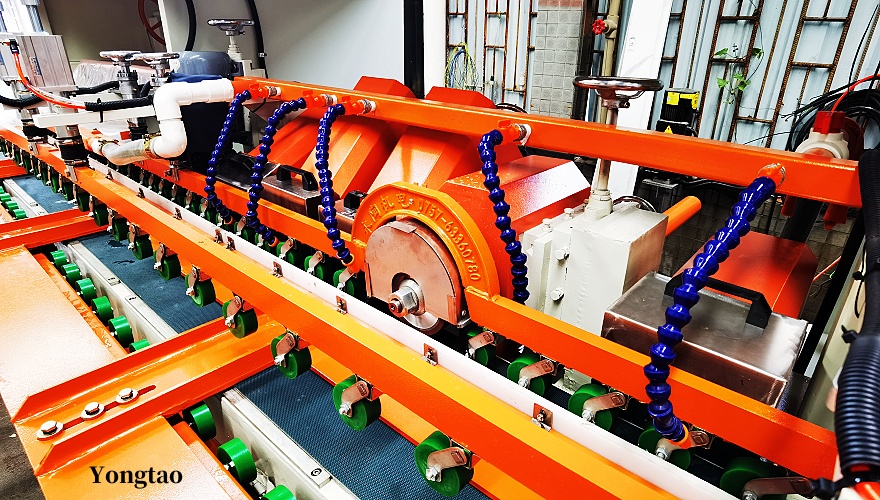

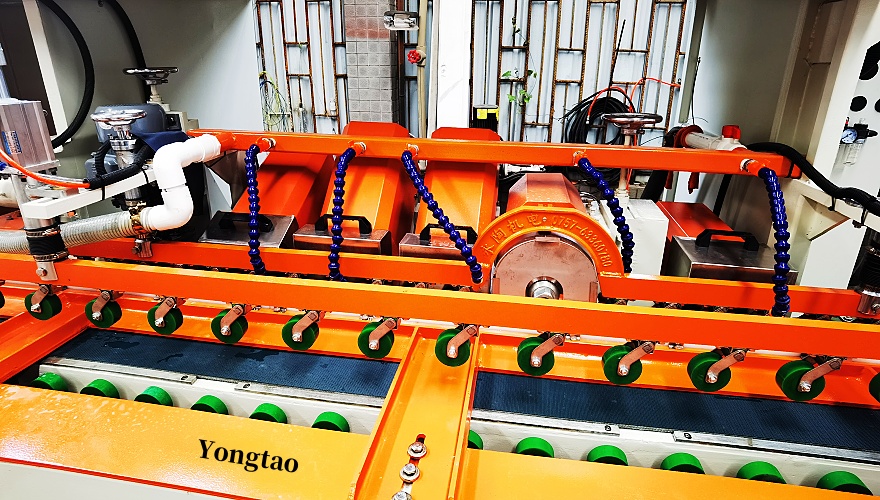

The YTYP-1600/6+8 Tile Edge Rounding Machine is the latest high-performance equipment from Foshan Yongtao Machinery, specially designed for ceramic processing, with a maximum processing width of up to 1600mm. This device integrates advanced technology and multifunctional capabilities, making it widely used in the modern ceramic tile processing industry. Through technological innovation and upgrades, the 6+8 ceramic tile round edge machine offers customers a more efficient and precise processing experience, making it a standout in the Chinese ceramic processing machinery market.

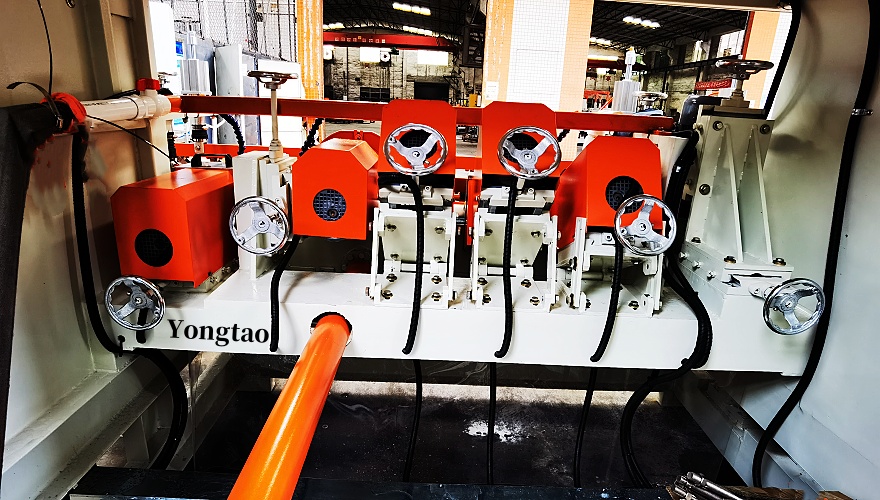

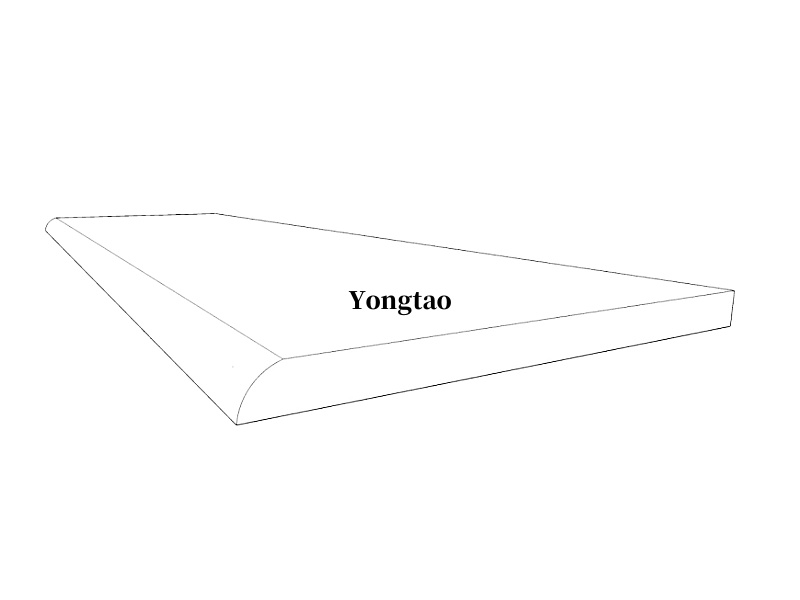

This ceramic tile rounding machine offers a variety of processing functions, including straight edge grinding, chamfering, grooving, and arc polishing. It can perform chamfering at different angles (such as 30 degrees, 45 degrees, and rounded edge forming) and complete comprehensive applications for round edge processing. Its precise grinding and polishing processes ensure that every product meets high standards of appearance and quality, providing customers with comprehensive solutions from home decoration to large-scale engineering projects.

The ceramic tile edge rounding machine is not only suitable for conventional ceramic tile processing but is also widely used in places with high decorative requirements such as home decoration and hotel projects. Especially in the processing of tile stair steps, skirting boards, and L-shaped ceramic and stone materials, the ceramic tile edge polishing machine has shown excellent flexibility and efficiency, providing high-quality decorative effects for various projects and enhancing the overall aesthetic of the space.

To ensure processing precision and efficiency, the ceramic tile edge polisher is equipped with high-quality polishing heads and diamond grinding wheels. The polishing head has a diameter of 95mm, and the diamond grinding wheels come in sizes of 200mm and 150mm, with the grooving blade diameter being 150mm. These high-quality components not only enhance the stability of the equipment but also significantly improve the processing results, enabling the machine to flexibly handle various specifications, ensuring high production efficiency and superior processing performance.

The ceramic tile stair step processing machine demonstrates excellent performance in various application scenarios. It can finely process ceramic tile stair steps, making it widely used in home and hotel decoration, enhancing both the aesthetics and functionality of the space. For skirting boards, the porcelain tile edge polisher can perform precise arc processing, ensuring a perfect combination of the skirting board with the floor and walls, greatly improving the overall decorative effect. For L-shaped groove processing, the tile edge polisher can perform grooving on the tile edges, creating a three-dimensional visual effect that adds distinct layers to the wall, bringing a unique design aesthetic.

The 6+8 ceramic tile stair step polishing machine launched by Yongtao Machinery demonstrates exceptional technical advantages in both design and performance. With continuous technological improvements and innovations, this equipment has reached industry-leading levels in multifunctional and high-precision processing. Its unique design philosophy and precise understanding of customer needs have set a new benchmark in the Chinese ceramic processing machinery industry, driving the development of the entire industry.

With its multifunctionality and excellent processing capabilities, this edge rounding machine significantly improves the production efficiency and product quality of ceramic tile processing factories. The equipment, operating with high efficiency and stability, can greatly reduce processing time, enhance the overall quality of the product, and lower production costs. This has earned the equipment wide recognition and popularity in both domestic and international markets, creating more market competitiveness and economic benefits for enterprises.

As a leading company in the Chinese ceramic machinery equipment industry, Foshan Yongtao Machinery is committed to technological innovation and equipment upgrades. The YTYP-1600/6+8 Ceramic Tile Edge Rounding Machine not only achieves new breakthroughs in technical performance but also promotes the ceramic processing industry toward high efficiency and intelligence. In the future, Yongtao Machinery will continue to lead industry trends, providing customers with more high-quality equipment and services, contributing to a more prosperous future for the ceramic processing industry.

Technical parameters:

Serial Number | Name | Parameter |

1 | Conveyor Belt Width | 300mm |

2 | Number of Edge Grinding Heads | 1 |

3 | Power of Edge Grinding Motor | 3kw |

4 | Diameter of Edge Grinding Wheel | Φ200x60mm |

5 | Number of Slotting Grinding Wheels | 1 |

6 | Power of Slotting Motor | 3kw |

7 | Diameter of Slotting Wheel | Φ150x30mm |

8 | Number of Slots | 3 - 4 |

9 | Number of 45 Degree Chamfering Grinding Heads | 2 |

10 | Power of 45 Degree Chamfering Motor | 3kw |

11 | Diameter of 45 Degree Chamfering Grinding Wheel | Φ200x600mm |

12 | Number of 30 Degree Chamfering Grinding Heads | 1 |

13 | Power of 30 Degree Chamfering Motor | 3kw |

14 | Size of 30 Degree Chamfering Grinding Wheel | Φ200x600mm |

15 | Number of Round Edge Forming Wheels | 1 |

16 | Power of Round Edge Forming Motor | 3kw |

17 | Diameter of Round Edge Forming Wheel | Φ180x25xR10mm |

18 | Number of Polishing Grinding Heads | 8 |

19 | Diameter of Polishing Grinding Head | Φ95 (Y6)mm |

20 | Power of Polishing Head Motor | 1.5kw |

21 | Power of Transmission Motor | 2.2kw |

22 | Power of Baffle Motor | 0.75kw |

23 | Processing Width | 70 - 1200mm |

24 | Polishing Speed | 1 - 5m/min |

25 | Processing Thickness | 6 - 20mm |

24 | Total Power | 29.95kw |

25 | Machine Size | 510022002130mm |

26 | Weight | About 3650kg |

[email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China