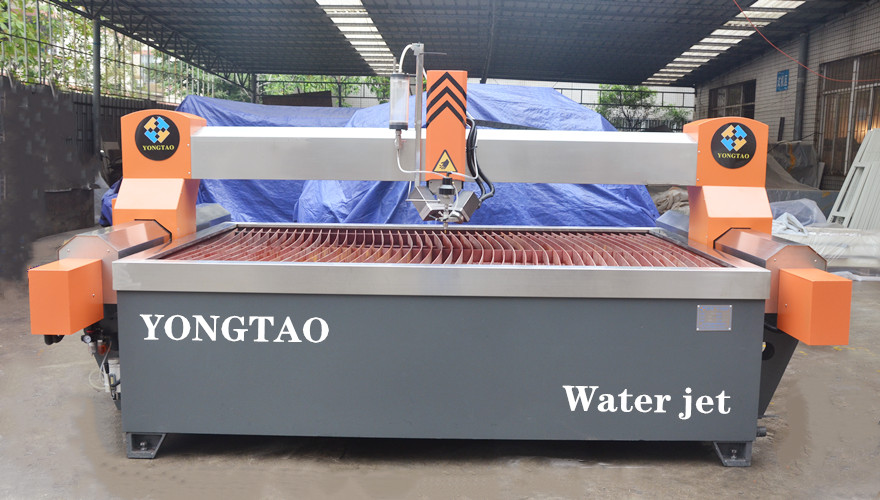

Product name: YJ-2515-5L 5 axis Cnc Water Jet Cutting Aluminum Machine(YJ-2515-5L 5 Axis High Pressure Metal Water Jet Cutter)

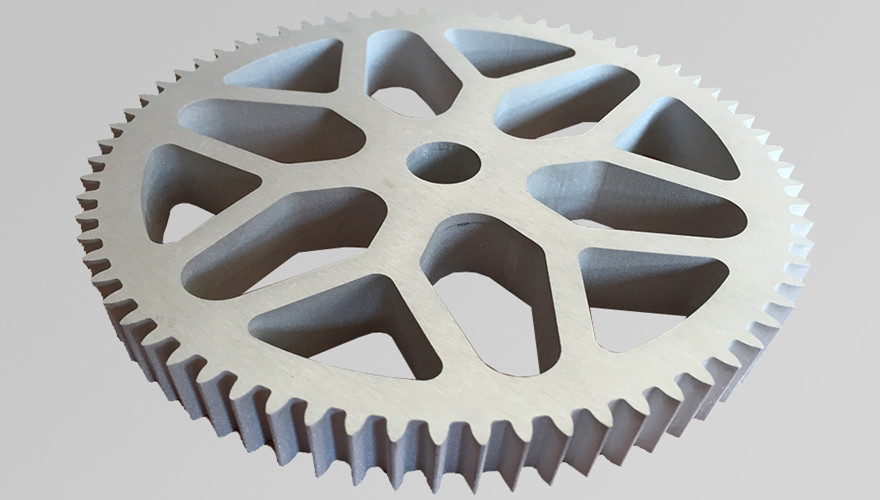

Processing materials: metal, glass, ceramic tile, stone, steel plate, aluminum plate, leather, stainless steel, quartz stone, marble, granite, alloy steel, artificial stone and other materials cutting processing

Origin: Foshan, Guangdong, China

Brand name: YONGTAO

Mode of transport: By Sea or railway (container transport)

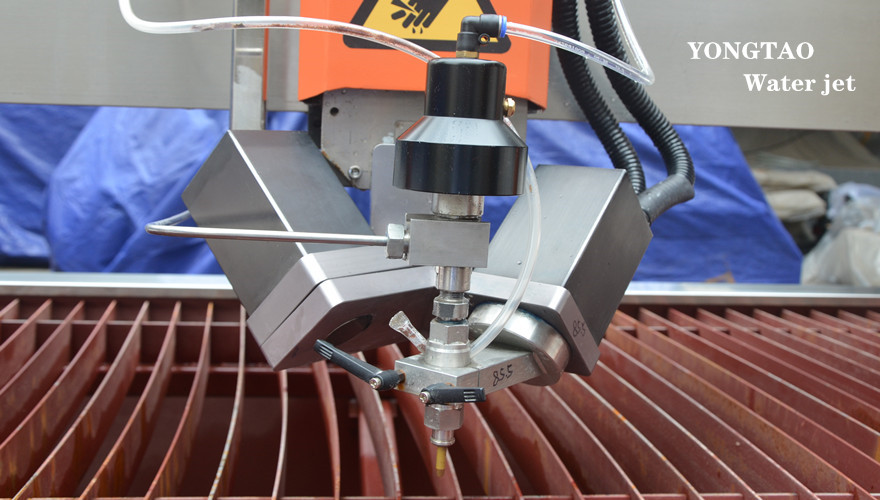

Yongtao 2515 AB 5 axis CNC water jet cutting machine, it can realize the angle cutting of the 0 to 10 degrees, more commonly used specifications relatively small sheet metal cutting, such as: metal, ceramic tile, aluminum plate, sheet, composite materials. 5 axis cutting can be in any direction of inclined angle of the cutting tools for cutting, eliminates the cut surface uneven phenomenon, eliminate the small ion bottom and big on top phenomenon). It can make complex graphics more meticulous, elegant, and simple, cutting corners without pause, without turning the dots, cutting speed faster, smaller aperture, cut surface more smooth, make it meet the customer's processing requirements.

The 5 axis CNC water jet cutting machine can adjust the angle freely according to different cutting requirements, due to the high pressure water jet cutting is the flexible cutting, water cutting, compared with 3 axis water jet cutting, cutting out the product section will have a certain slope, in the field of some high precision products cutting, as much as possible in order to ensure the cutting section of vertical, we must reduce the cutting speed. While 5 axis water jet cutting through angle compensation, ensure the 5 axis water jet cutting work-piece interface angle can be the angle of the relative degree compensation, so that the products cut out, does not need second grinding can achieve seamless splicing, save time and labor, efficient and perfect, Yongtao high pressure five axis CNC water jet cutting machine has been used by many

1. AB 5 axis structure design is adopted to realize the linkage of CNC five-axis (X, Y, Z, A and B).

2. Imported reducer is adopted, with few parts, brief structure, beautiful appearance, simple operation, easy to learn and convenient maintenance.

3. Yaskawa servo motor is adopted to effectively improve the cutting speed and control accuracy.

4. Do not use rotary joint, greatly reduce the number of wearing parts, reduce the user's use cost.

5. The use of integrated dust proof sealing structure, improve the service life of mechanical equipment.

6. Adopt the original imported linear guide rail and screw lifting structure to make the whole 5 axis cutting tool head more stable and reliable.

1. Compared with the traditional water jet cutting machine, the production efficiency is increased by 30-200%

2. Can improve the speed of cutting work piece cutting surface quality

3. Lower production cost

4, unique positioning design, improve the accuracy and reliability of positioning, ensure that the cutting head after each dis-assembly precision unchanged

5. Adjust deviation Angle automatically through CNC control system, which is convenient and reliable

6. Cutting surface cavity, cutting tool head can be close to the inner wall of the work piece, will not interfere with the work piece.

1. Water jet cutting table

2. CNC water jet control system

3. Abrasive supply system

4. Water jet ultra-high pressure supercharging system

5. Circulating cooling tower

Package size of 5 axis water jet cutting table: 3.8m*2.35m*1.65m

Package size of water jet supercharger: 1.3m*0.95m*1.25m

Package size of water jet sand supply system: 0.6m*0.6m*0.95m

Package size of CNC water jet control system: 0.65m*0.65m*1.67m

Gem, sand pipe

High pressure water cycle

Water switch seal ring

Water switch thimble

Water switch spherical valve pad

Valve core, valve pad, garnet sand

Maximum cutting thickness of metal: 40mm

Maximum cutting thickness of ceramic tile, stone, glass, artificial stone, quartz stone, marble and granite: 50mm

Maximum cutting size: 2500mm*1500mm

Machining accuracy :±0.1mm

Gem nozzle diameter: 0.33mm

Nozzle size of sand pipe: 1.0mm

Maximum displacement: 11.1l /min

Maximum sand usage: 190g/min

Maximum stroke: 60 strokes /min

Hydraulic oil: no.46 or no.68 (Great Wall hydraulic oil)

Power supply :220V/380V/415V, 50/60hz

Computer drawing software: Auto CAD drawing software

Operating system: Windows XP

Z-axis travel: 130mm

Maximum pressure: 420Mpa

Working pressure: 300-380mpa

Main motor power: 30kw

Total power: 37kw

Parameter of YJ-2515-5L 5 Axis High Pressure Metal Water Jet Cutter

|

Model |

YJ-2515-5L |

|

|

Structure |

Bridge |

|

|

Cutting table size |

2600x1600mm |

|

|

Stroke |

X-axis |

2500mm |

|

Y-axis |

1500mm |

|

|

Z-axis |

130mm |

|

|

CNC Controller |

AC Servo System |

|

|

Accuracy |

Cutting |

±0.1mm |

|

Repeat ability |

±0.05mm |

|

|

Traverse speed |

6000/15000 mm/min |

|

|

Power source |

380VAC, 50Hz, 3Phase |

|

[email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China