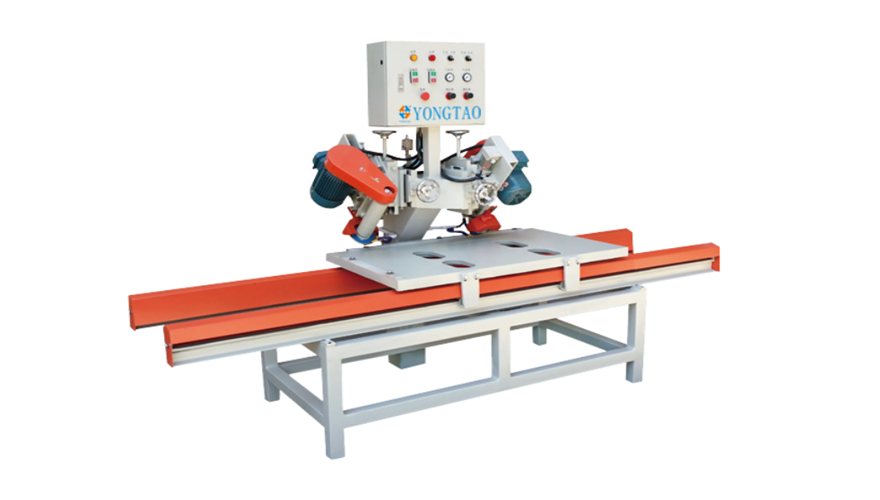

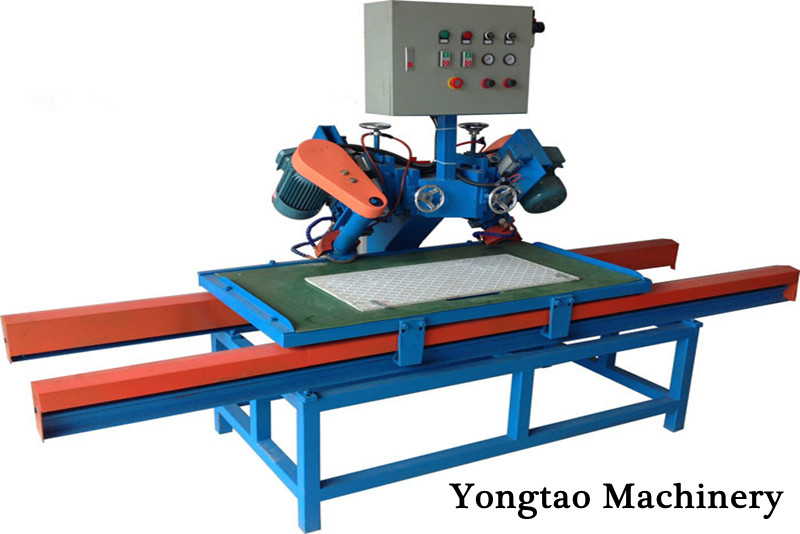

Description of YTQKS-1200 Ceramic Tile Back Grooves Cutting Machine

YTQKS-1200 Ceramic Tile Back Grooves Cutting Machine is used for making grooves on the back of tile,which is used for dry hang up tiles on the wall. Ceramic groove cutting machine have two cutting heads,which can be automatically sensed and lifted.It can be horizontal adjusted the width of two grooves. The lifting of cutting head is driven by air cylinder,and the height and angles of cutting head also can be adjusted.The cutting heads are controlled by travel switch to control cutting distance,single trip can make 2 grooves.

ceramic tile hanging slotting machine:

The cutting head installed on one the side of the platform, which adopts cast iron materials. The worker push the platform to the cutting area. It adopts wet type cutting, whole processing need water for cooling,to avoid the lack of water and burning blade and damage ceramic tile. The machine need to be equipped with a air compressor. During the process of cutting head down, the cylinder needs to use gas.

The machine has the advantage of semi-automation control with low cost, simple operation, good effect of grooves. Due to the reasonable designing, this machine does not chipping. It is popular in most of tile processing factories, storefront, etc.

Technical Parameter of YTQKS-1200 Ceramic Tile Back Grooves Cutting Machine|

Motor power |

3kw*2pc=6kw |

|

Function |

Grooving on the back of tile |

|

Size of machine |

2.7*1.3*1.8m |

|

Diameter of blade |

(110-130)*20*2.0mm |

|

Voltage |

220/380V |

|

Weight |

约300kg |

|

Specification of processing |

300*600mm、400*800mm、500*1000mm、600*1200mm |

|

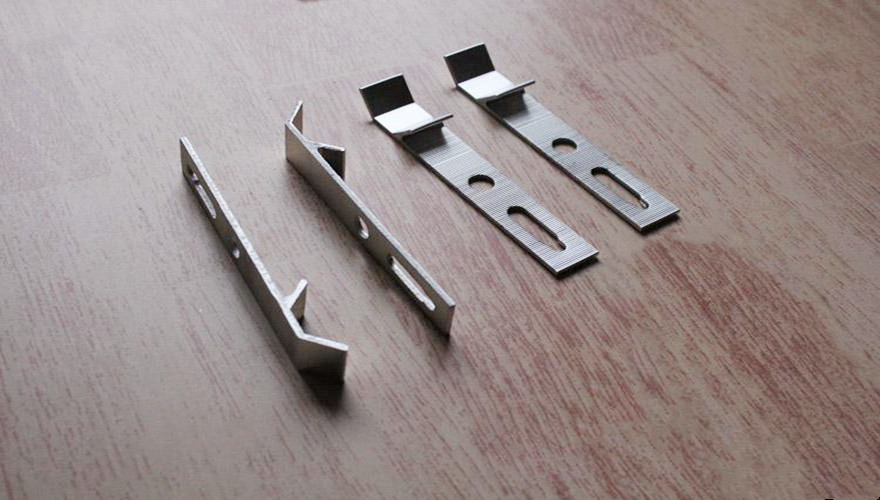

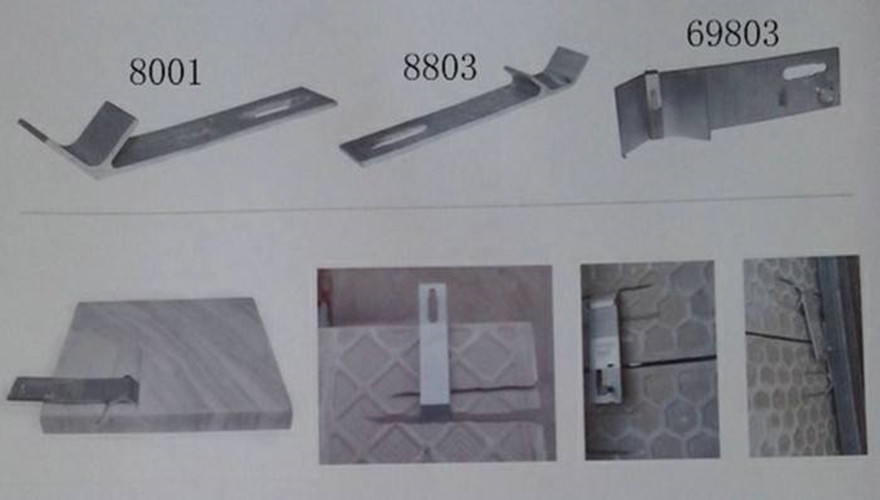

Dry hang tool |

8001 type groove width27mm 8803type groove width 28mm 69803type groove width40mm Materials: Aluminium alloy |

|

Processing method |

Dry hang up |

|

Processing materials |

Ceramic tile, stone slab |

[email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China