The reason why the quartz stone 45-degree chamfering machine chooses 7 heads is to improve processing efficiency and versatility. The equipment has multiple functions such as pre-cutting, cutting, grooving, trimming and chamfering. Among them, the chamfering function is equipped with three 45-degree chamfering heads, which can quickly and accurately perform chamfering. In addition, the belt-type structure of the quartz stone 45-degree chamfering machine, the upper and lower pressure beams of solid carbon steel, and the overall annealing heat treatment and other excellent features ensure the processing accuracy and stability. The PLC control system adopts the Japanese Omron brand to ensure the stability and reliability of the equipment. At the same time, the overall brick bracket of the quartz stone 45-degree chamfering machine is made of aluminum alloy profiles, which is easy to install, durable, and has a high cost performance. Based on the above advantages, the equipment has great advantages in processing efficiency, processing quality, stability and durability.

In addition, the quartz chamfering machine also has a lower processing cost, and the processing fee for 1 meter is about 0.45 yuan, which can effectively improve production efficiency and economic benefits. The chamfering angle is 45 degrees, the hypotenuse has grooves, and the bonding glue is stronger, ensuring that the processed rock slabs are more beautiful, durable. Double saw blades cut quartz stone at 45 degrees faster, which can greatly shorten the processing time. In addition, the thickness limit function of the quartz stone 45-degree chamfering machine and the automatic protection of the lifting height of the pressure beam improve the safety and stability of the equipment and reduce the maintenance cost of the equipment. The minimum processing is 30mm, and the maximum processing is 3.8 meters, which can meet the processing needs of rock slabs of different sizes and provide users with more comprehensive and flexible choices. The man-machine interface starts with one button, and the operation is easy to learn, which reduces the difficulty of equipment operation and the cost of personnel training. To sum up, the quartz stone chamfering machine has many advantages such as multi-function, high efficiency, high precision, good stability, strong durability, and economic benefits. It is an excellent quartz stone countertop processing machine.

In addition to the advantages mentioned above, Yongtao quartz stone chamfering machine also has the following characteristics and advantages:

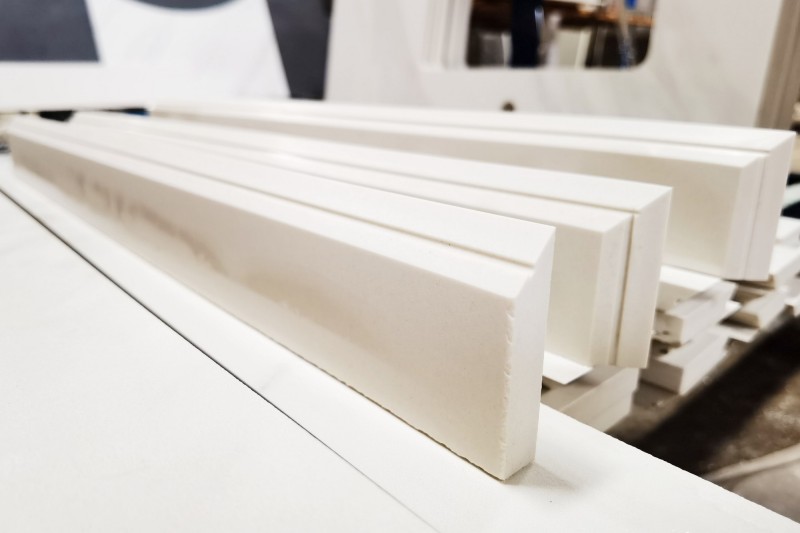

High-precision processing: The quartz stone 45-degree chamfering machine adopts a belt-type structure and a solid carbon steel material for upper and lower pressure beams. After an overall annealing heat treatment, the processing accuracy can be guaranteed to be plus or minus 0.1mm, ensuring the quality of the processed quartz stone and sintered stone. Precise specifications, beautiful and durable.

High degree of automation: The equipment adopts PLC control system to realize automatic control, operate through the man-machine interface, one-button start, simple and convenient operation, and improve production efficiency and product quality.

Strong versatility: The quartz stone chamfering machine is equipped with multiple functional heads, which can realize various processing such as pre-cutting, cutting, grooving, trimming, and chamfering, and can meet different processing needs.

High equipment reliability: The equipment adopts the integral brick bracket of aluminum alloy profiles, which is easy to install, durable, and has high corrosion resistance and wear resistance, which can improve the reliability and life of the equipment.

Good safety performance: The quartz stone 45-degree chamfering machine has the functions of thickness limit and automatic protection of the lifting height of the pressure beam, which can avoid misoperation and damage of the equipment, and improve the safety and stability of the equipment.

To sum up, the quartz stone 45-degree chamfering machine has many advantages and characteristics, which can not only meet the processing needs of users, but also improve processing efficiency, improve product quality, and reduce production costs. It is a recommended quartz stone Mesa processing machinery.