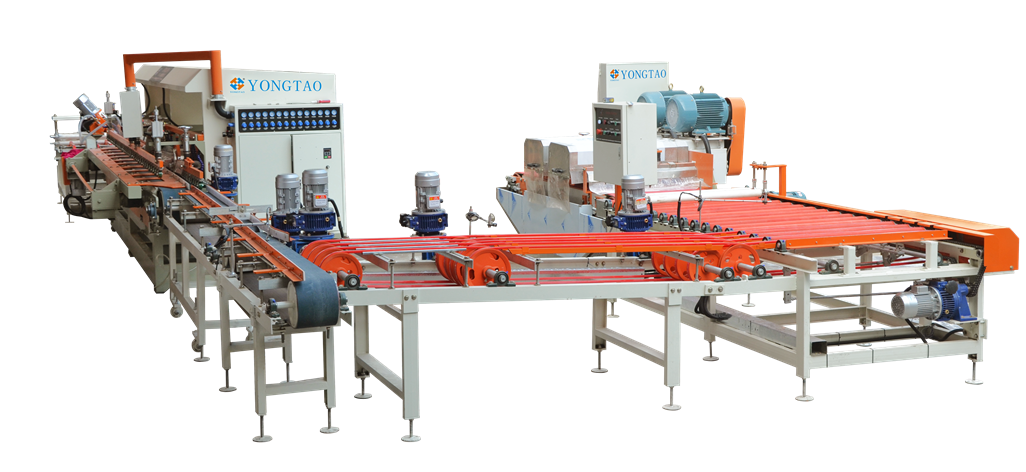

The Yongtao Two-Spindle Wet Tile Cutting Machine features a dual-spindle design, with each spindle capable of accommodating multiple cutting blades. This machine is suitable for cutting and strip-cutting various building materials, including tiles, stone, mosaics, sintered stone, PC bricks, quartz stone, and cement bricks, meeting diverse building material processing needs. It offers high cutting precision and speed, making it ideal for factories to perform multiple cuts in a single operation, significantly enhancing production efficiency and earning widespread acclaim within the industry.

This machine is versatile and user-friendly, especially suited for export to overseas customers. Its well-engineered structure and large cutting blades deliver impressive results, ensuring neat and smooth edges, further enhancing material processing quality and product value. The design thoughtfully considers the needs of different users, with wet-cutting capabilities that effectively reduce dust and heat, improving both cutting efficiency and workplace comfort.

The Yongtao Wet Tile Cutting Machine offers notable advantages. First, its dual-spindle design increases cutting efficiency, allowing multiple blades on each spindle to perform several cuts simultaneously. Second, it provides high cutting precision, producing smooth, finely finished products that cater to clients with stringent accuracy requirements. Third, the machine's fast cutting speed meets the high-efficiency demands of modern production environments.

Additionally, we offer customized production to suit different national voltage standards, flexibly meeting the needs of global clients. Whether adjusting voltage standards or optimizing performance, we provide personalized services to ensure equipment compatibility and stability. Thanks to its efficiency, durability, and user-friendly operation, this machine has earned high praise from international customers.

In summary, the Yongtao Wet Tile Cutting Machine, with its excellent performance, superior cutting quality, and strong adaptability, has become an indispensable tool for building material processing factories. Whether for large-scale production or small-batch processing, this machine can meet a variety of needs, making it the ideal choice for enhancing productivity and product quality.

YSXP-150 6 Head Automatic Marble Profiling Polishing machine

10 30,2019

YSXP-150 6 Head Automatic Marble Profiling Polishing machine

VIEW

YSXP-150 6 Head Automatic Marble Profiling Polishing machine

10 30,2019

YSXP-150 6 Head Automatic Marble Profiling Polishing machine

VIEW YTQZ-A/2-1200 Two Blade CNC Ceramic Tile Cutter

10 30,2019

YTQZ-A/2-1200 Two Blade CNC Ceramic Tile Cutter

VIEW

YTQZ-A/2-1200 Two Blade CNC Ceramic Tile Cutter

10 30,2019

YTQZ-A/2-1200 Two Blade CNC Ceramic Tile Cutter

VIEW 5 Axis CNC water jet cutter machine

10 30,2019

YJ-2015-5L AB 5 Axis CNC Water Jet Cutting Machine

VIEW

5 Axis CNC water jet cutter machine

10 30,2019

YJ-2015-5L AB 5 Axis CNC Water Jet Cutting Machine

VIEW YTQZ-B/2-800 Double Spindle Multi Saw Blade Tile Cutting Machine

04 02,2019

YTQZ-B/2-800 Double Spindle Multi Saw Blade Tile Cutting Machine,This is two spindle tile cutting machine,it is specialized to cut tile strips.It can install 7-8 blades on each spindle,which can cut the tile into several strips in one time.For example, cu

VIEW

YTQZ-B/2-800 Double Spindle Multi Saw Blade Tile Cutting Machine

04 02,2019

YTQZ-B/2-800 Double Spindle Multi Saw Blade Tile Cutting Machine,This is two spindle tile cutting machine,it is specialized to cut tile strips.It can install 7-8 blades on each spindle,which can cut the tile into several strips in one time.For example, cu

VIEW YTYP-1200/7+14 Porcelain Tile Bullnose Machine

04 02,2019

YTYP-1200/7+14 Porcelain Tile Bullnose Machine,The ceramic tile bullnose machine is applied to the deep processing of ceramics, for example: edging, chamfering (30 degree,45 degree, 60 degree), bottom chamfering, grinding bullnose, polishing (bull

VIEW

YTYP-1200/7+14 Porcelain Tile Bullnose Machine

04 02,2019

YTYP-1200/7+14 Porcelain Tile Bullnose Machine,The ceramic tile bullnose machine is applied to the deep processing of ceramics, for example: edging, chamfering (30 degree,45 degree, 60 degree), bottom chamfering, grinding bullnose, polishing (bull

VIEW YTQZYP-1000 Two Spindle Ceramic Cutting And Tile Bullnose Polishing Machine

05 29,2019

YTQZYP-1000 Two Spindle Ceramic Cutting Machine And Ceramic Tile Bullnose Polishing Machine,Two spindle tile cutting machine can install multiple blades on each of spindle. It can cut several tile strips in one time. The max cutting size of this two spind

VIEW

YTQZYP-1000 Two Spindle Ceramic Cutting And Tile Bullnose Polishing Machine

05 29,2019

YTQZYP-1000 Two Spindle Ceramic Cutting Machine And Ceramic Tile Bullnose Polishing Machine,Two spindle tile cutting machine can install multiple blades on each of spindle. It can cut several tile strips in one time. The max cutting size of this two spind

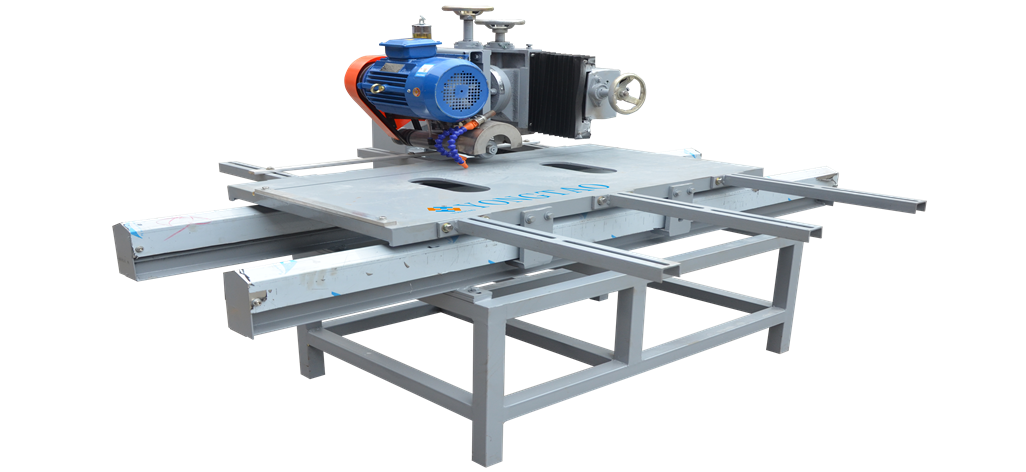

VIEW YTQS-2-1200 Manual Multifunctional Tile Cutting Machine

04 02,2019

YTQS-2-1200 Manual Multifunctional Tile Cutting Machine,The machine is a powerful deep processing machine for ceramic tile.It can do almost all of processing by this single one machine,such as cutting,grooving,edging,chamfering,grinding bullnose.It is

VIEW

YTQS-2-1200 Manual Multifunctional Tile Cutting Machine

04 02,2019

YTQS-2-1200 Manual Multifunctional Tile Cutting Machine,The machine is a powerful deep processing machine for ceramic tile.It can do almost all of processing by this single one machine,such as cutting,grooving,edging,chamfering,grinding bullnose.It is

VIEW YSU-1200 16 Head Stone Polishing Machine

05 24,2019

YSU-1200 16-head stone polishing machine, which can polish the surface of marble, stone, quartz stone, granite, and also can be used for the surface polishing of stone mosaics, as well as some small pieces of stone, the surface polishing treatment, the ma

VIEW

YSU-1200 16 Head Stone Polishing Machine

05 24,2019

YSU-1200 16-head stone polishing machine, which can polish the surface of marble, stone, quartz stone, granite, and also can be used for the surface polishing of stone mosaics, as well as some small pieces of stone, the surface polishing treatment, the ma

VIEW YTQZ-B/1-600 Single Spindle Tile Cutter For Mosaic Tiles

05 24,2019

Create wonderful mosaic artworks and installations with these mosaic tile cutter machines. Read on to find out more about them and how they can be useful.

VIEW

YTQZ-B/1-600 Single Spindle Tile Cutter For Mosaic Tiles

05 24,2019

Create wonderful mosaic artworks and installations with these mosaic tile cutter machines. Read on to find out more about them and how they can be useful.

VIEW

[email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China